|

|

#1401

|

||||

|

||||

|

Hello everybody,

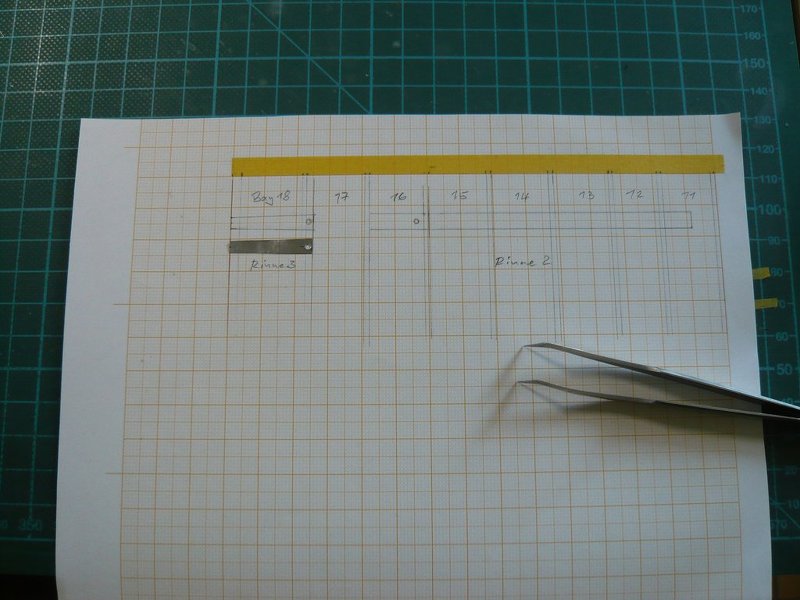

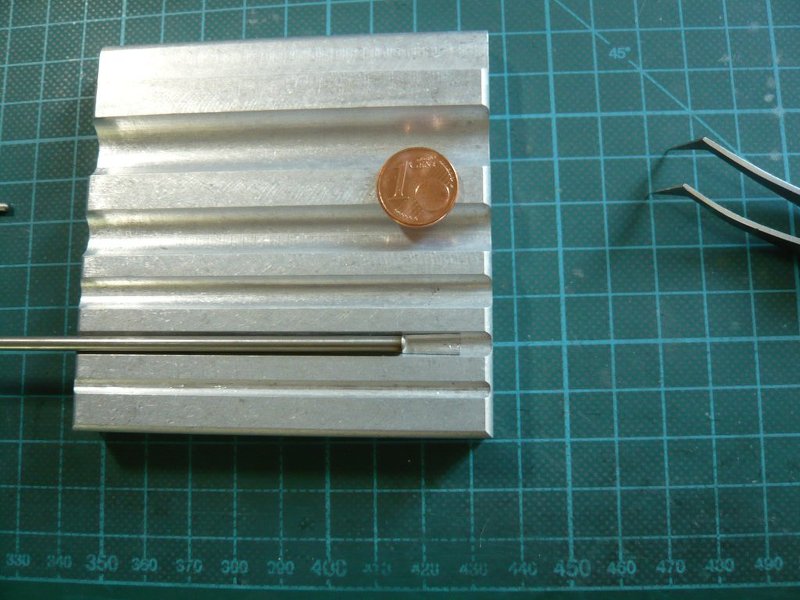

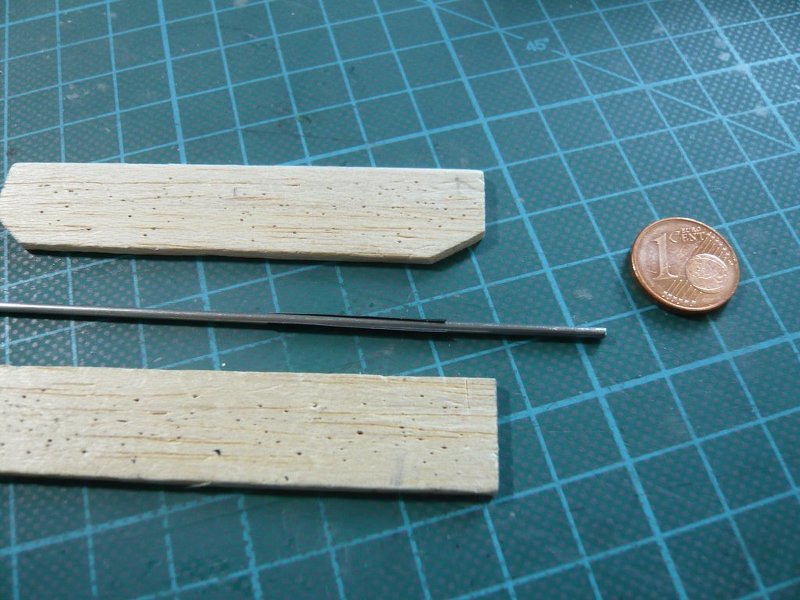

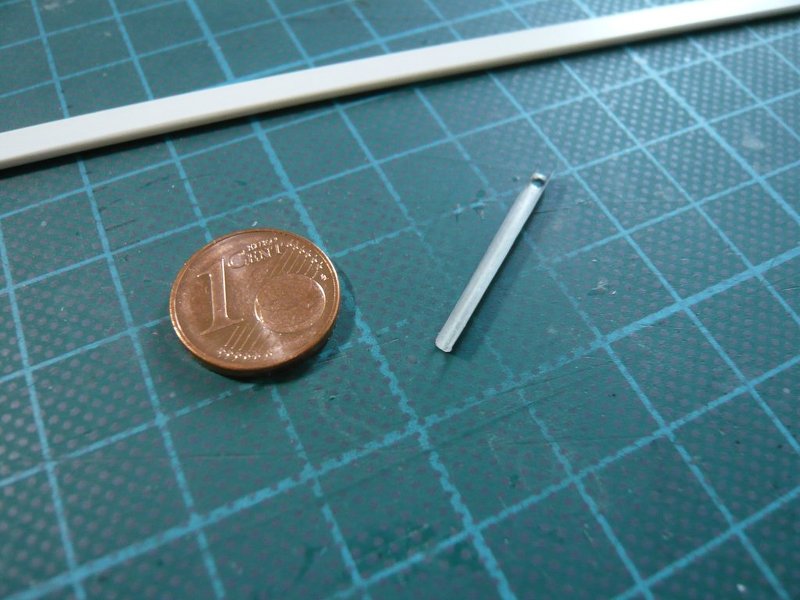

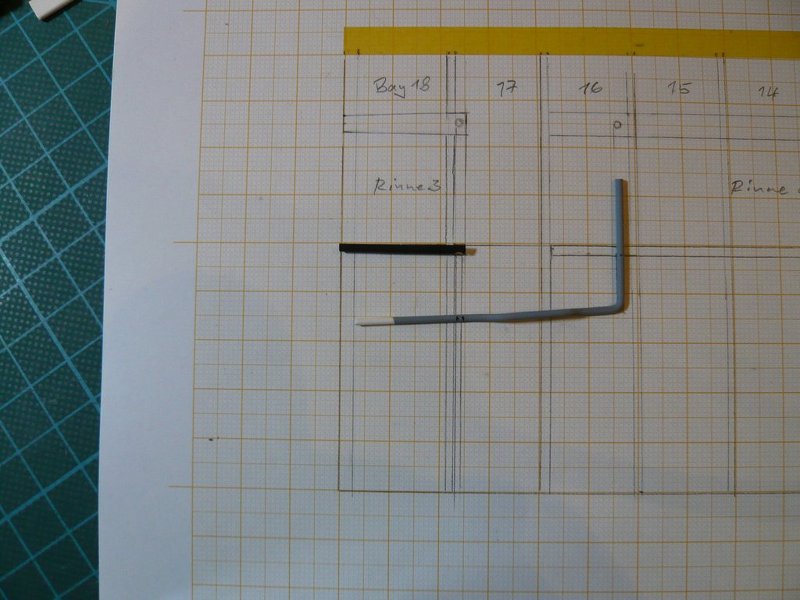

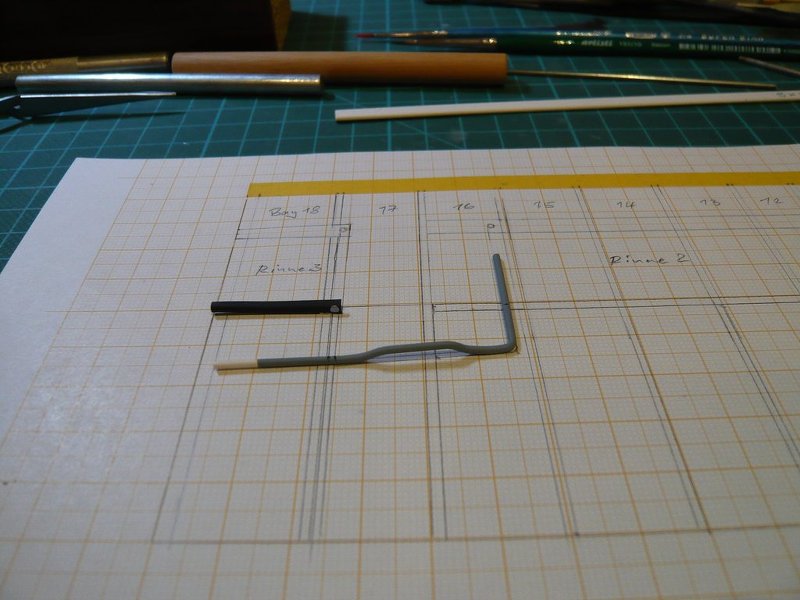

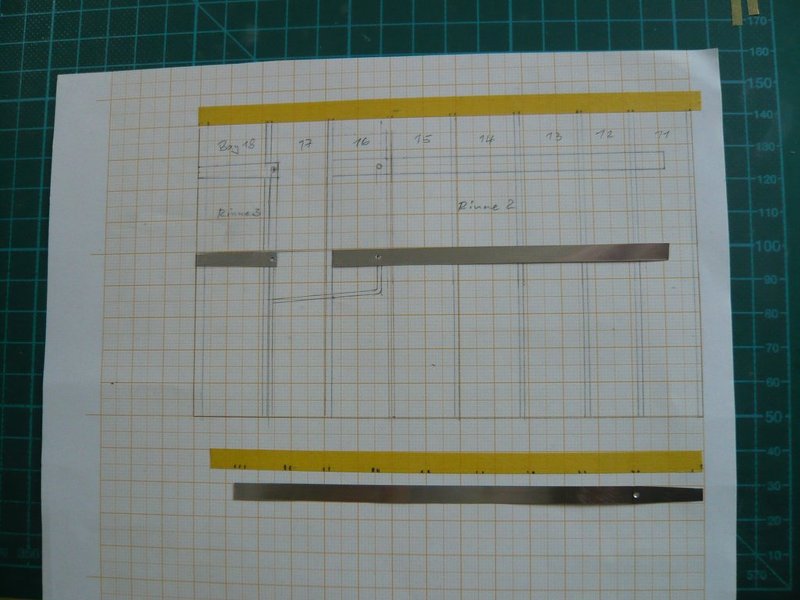

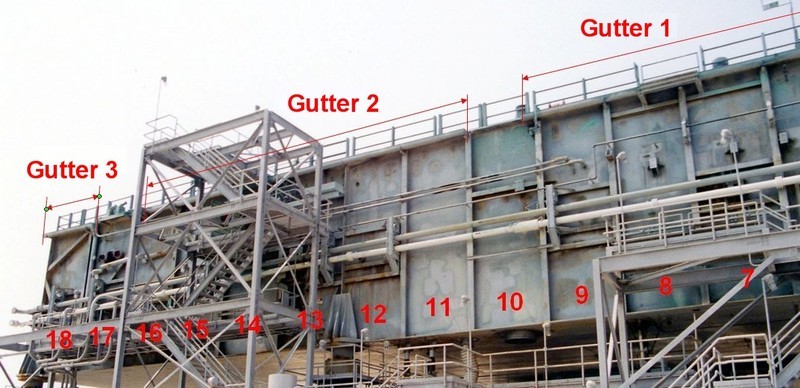

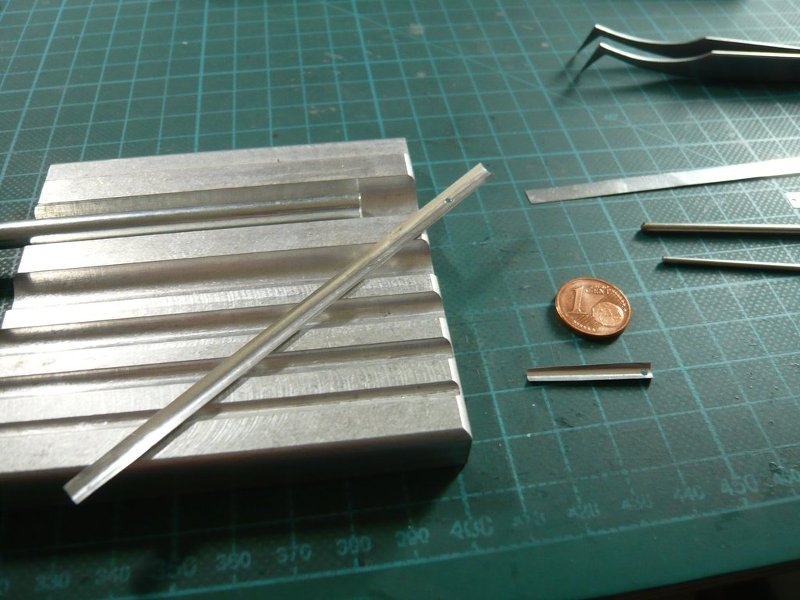

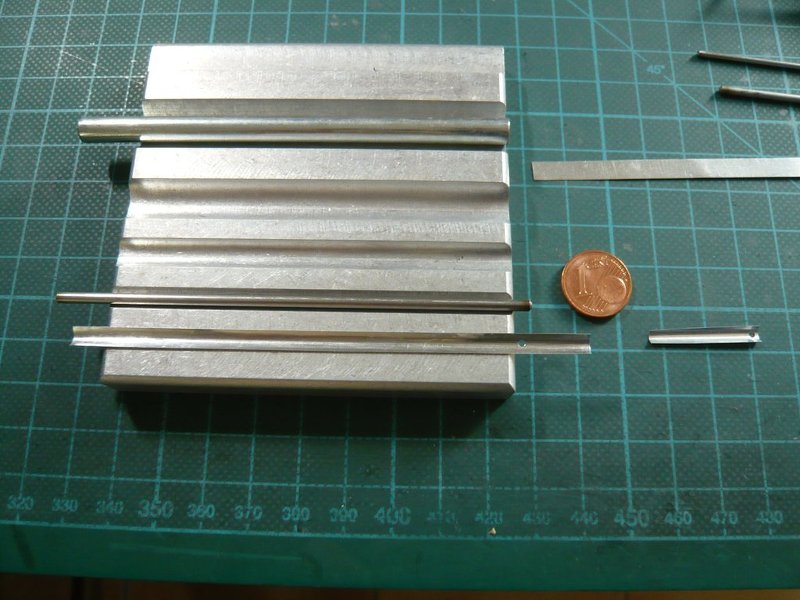

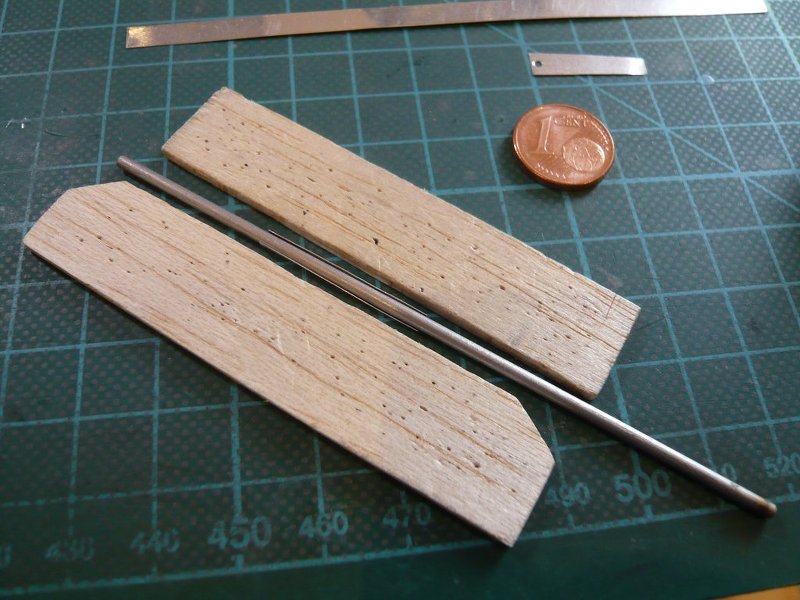

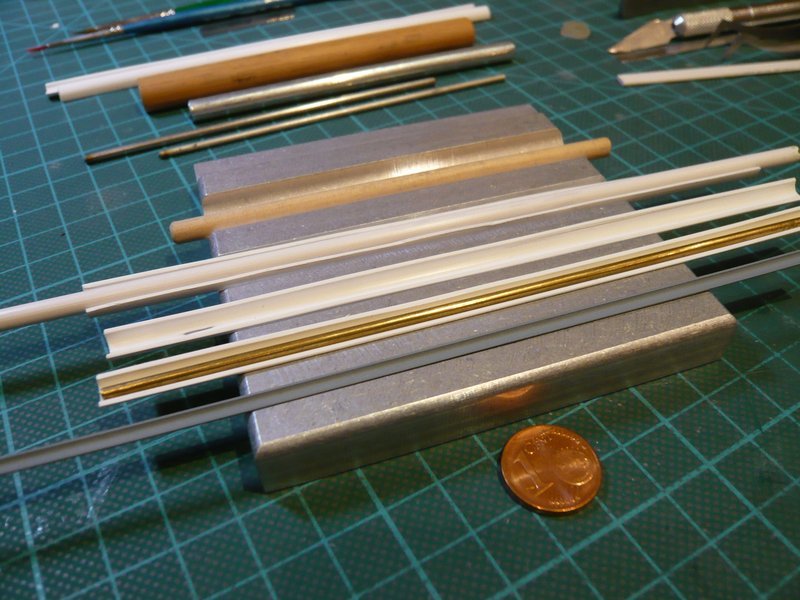

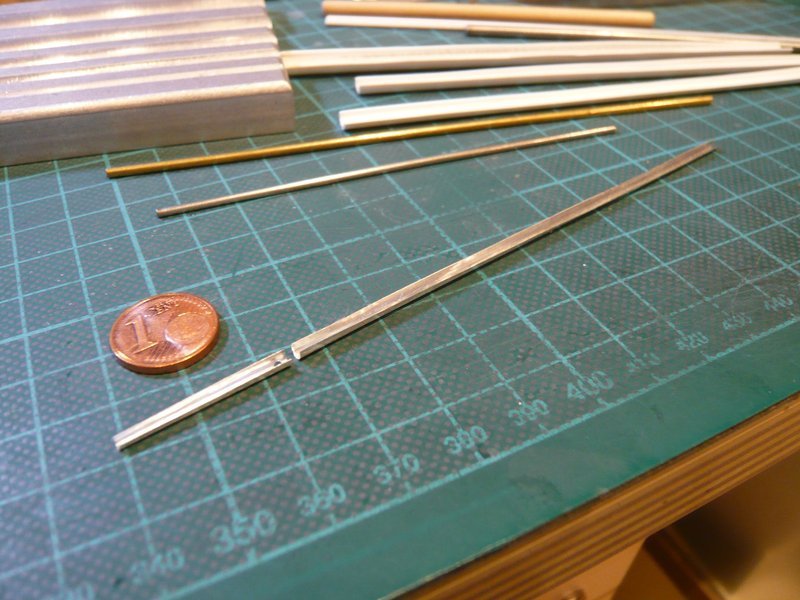

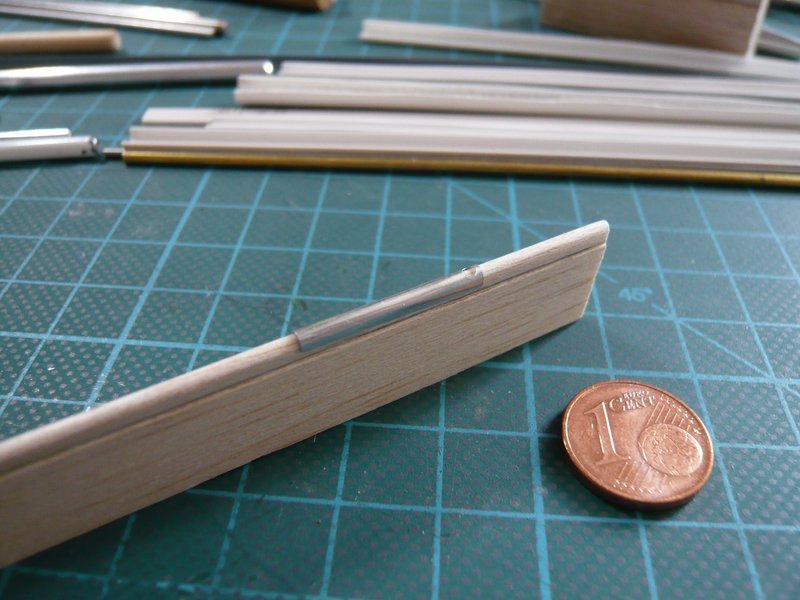

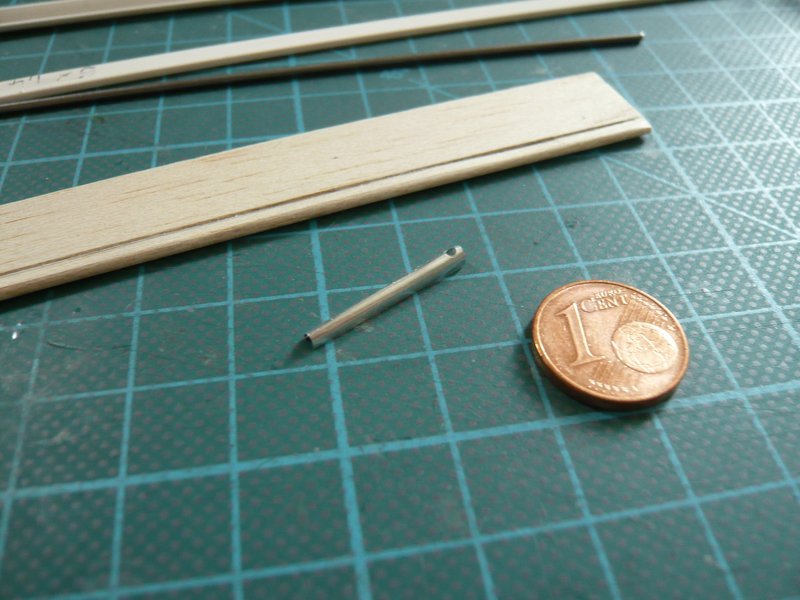

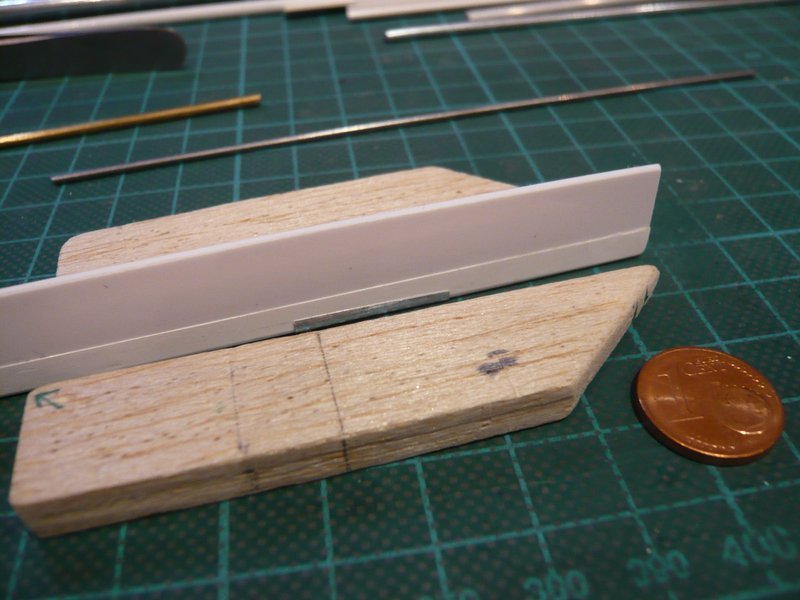

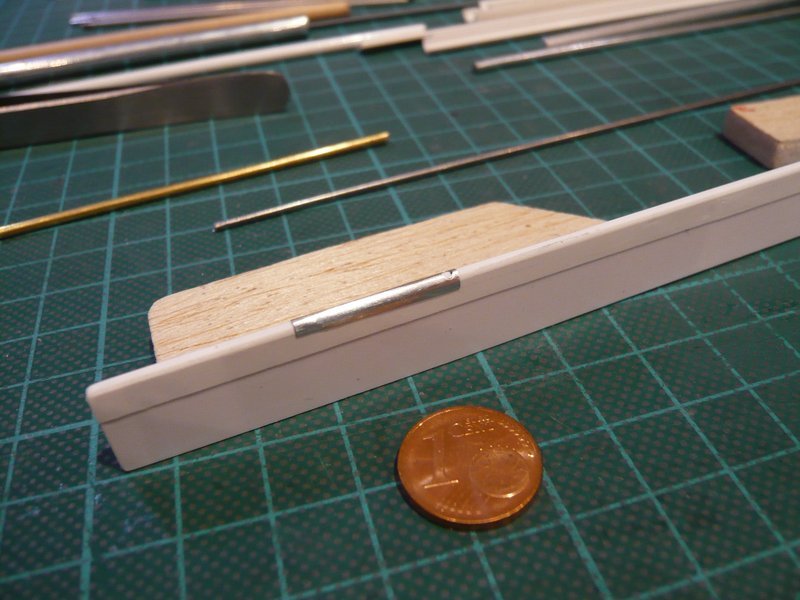

somehow I still miss the right bite for this gutters chapter,  but it does not help, and therefore I have to swallow this pill ... but it does not help, and therefore I have to swallow this pill ...  Therefore, I first have drawn a template for the making of the gutter parts, which is unfortunately somewhat pale,  and then I have cut a further sample strip for the Gutter-3 from a champagne cork foil, which slightly tapers to the corner, in order to get the appropriate gradient of this gutter part. The punched opening for the downspout (8'') is located at the beginning, immediately next to the girder at the end of the Bay 17, as can be seen in this image.  Source: Library of Congress And this stripe I then have pre-molded step-by-step on my Rolling Set,  by using core wires with decreasing diameters,   down to the last groove,  with this intermediate result.  For further molding of the gutter, I then have pressed the gutter with the core wire vigorously into a foam strip,  whereby unwanted kinks can be avoided, as can be seen.  Between two balsa slats the rounding was then still somewhat equalized.  Since the wider strip end inevitably gets rounded a little too far using the thinnest core wire (Ø 1.5 mm), the gutter part has been equalized again over a rounded plastic strip (5 mm x 1.5 mm) in order to obtain an U-shaped profile.   Here the gradient of the gutter can be seen very well already.  And here one can see the Gutter-3 in the side view with the prepared bended downspout, which is running into the downspout at the end of the Bay 16.   After this successful attempt, I can now also make the final Gutter-3 from the aluminum sheet (0.1 mm). The Gutter-2 will then be formed in an analogous manner, but this time immediately from an aluminum sheet strip of 99 mm × 5 mm, since its height is the same over the entire length. That's it so far, and thanks for looking.

__________________

Greetings from Germany Manfred Under construction: Launch Pad 39A with Challenger STS-6 (1:144) |

|

#1402

|

||||

|

||||

|

Hello everybody,

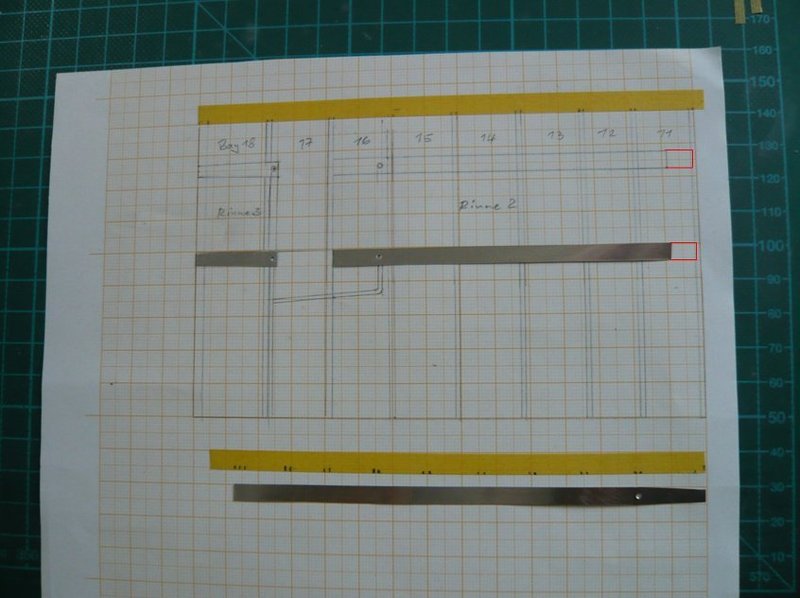

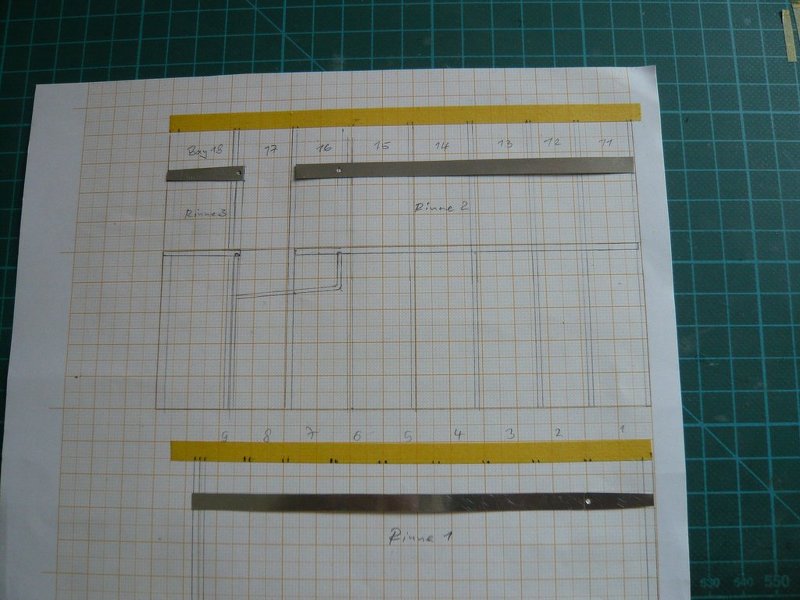

it goes on with the gutters.  The fact that the test results with the short gutter parts were quite promising doesn't have to mean anything, because whether the rounding of the longer gutters from the 0.1 mm aluminum sheet would be work well too, would still have to be shown.  At first the short Gutter 3 at the end of Side 2 (Bay 18) was cut out and its opening punched for the downspout,  and also the strips for the Gutter 2 and Gutter 1 (bottom).  The dimensions were taken from this image of the MLP-3, because it has almost no distortions and should correspond to the MLP-2.  Source: Library of Congress The Gutter 2 starts at the end of the Bay 16 directly behind the local girder and extends to the middle of the Bay 11.  And then I actually wanted to start with the rounding of the gutters,  but previously I had once again compared the distribution of the gutters and the position of the box with the Fire hose reel with the images of the MLP-2 from the collection of John Duncan and suddenly did not trust my eyes. but previously I had once again compared the distribution of the gutters and the position of the box with the Fire hose reel with the images of the MLP-2 from the collection of John Duncan and suddenly did not trust my eyes. For as one can see on this already known image,  the Gutter 2 is running up to the end of the Bay 11, the Gutter 2 is running up to the end of the Bay 11,  Source: apollosaturn.com (John Duncan) and must therefore be slightly longer than the already cut strip, namely 107 mm instead of 99 mm. Only good that I had compared once again.   So a new gutter had to be cut, which was done quickly.   Continuation follows soon ...

__________________

Greetings from Germany Manfred Under construction: Launch Pad 39A with Challenger STS-6 (1:144) Last edited by spacerunner; 07-13-2017 at 05:38 AM. |

|

#1403

|

||||

|

||||

|

And now the stepwise rounding of the parts could finally get started,

initially again with the short gutter part up to the lower groove, and then with the longer part,   what could have been made even relatively well up to the rounding in the last groove, although it would be better if the Rolling Set would be slightly wider.   Thereafter, the short piece was gradually further rounded, first on the foam strip,  and then between the balsa boards up to the core diameter of 1.5 mm.  The further rounding of the longer gutter was then somewhat more difficult because it is longer than the core wires, which has led to unsightly kinks, especially during rounding on the foam strip, which should be avoided, however, since they are difficult to remove.  That's why I've tried it on the cutting mat, but for this one needs a tight clamping in order to press with the Balsa boards from both sides, but this has not worked so well.  After that I have the gutter again somewhat widened and tried it once more with a longer plastic profile, only the plastic is of course not stiff enough,  which is why I have stopped for the moment.  But, of course, I will not abandon immediately,  rather I will try it again with longer core wires, wherefore you could keep your fingers crossed, if you please! rather I will try it again with longer core wires, wherefore you could keep your fingers crossed, if you please! Maybe one of you still has a smart tip for me, which would be very helpful.

__________________

Greetings from Germany Manfred Under construction: Launch Pad 39A with Challenger STS-6 (1:144) |

|

#1404

|

||||

|

||||

|

Hello together,

here I am again, but unfortunately with the previous low point of my gutter-rounding ...   And what does one say thereto?  I had just cut off a longer brass core wire (Ø 2.0 mm) and wanted to try again, to smooth the little dents, but a longitudinal kink which meanwhile had developed caused by the multiple rounding of the strip was then too much for the thin sheet, which unfortunately has broken up, caused by material fatigue ...  And what is that teaching us? Unnecessary back-and-forth bending should be avoided as far as possible, and stepwise be rounded in only one direction, which I will now try again cheerfully with longer core wires and a new strip.

__________________

Greetings from Germany Manfred Under construction: Launch Pad 39A with Challenger STS-6 (1:144) |

|

#1405

|

||||

|

||||

|

Hello friends,

since these crazy gutters are always on my mind, I am constantly pondering how I can master them ...  And then tonight during a cool wheat beer  (Cheers!!!) I hit on an idea, (Cheers!!!) I hit on an idea,  that in my very first attempts to build such gutters I had used the smallest available Styrene half-pipe (Ø 3.0 mm), on the left in the image, which was however too big for my 1:160 scale and was quickly put aside. that in my very first attempts to build such gutters I had used the smallest available Styrene half-pipe (Ø 3.0 mm), on the left in the image, which was however too big for my 1:160 scale and was quickly put aside.   But this half-pipe could at least be a suitable support for the final rounding of the gutters with the 1.5 mm core wire after the last groove in the set,  which would also be long enough for the longer gutter parts,

__________________

Greetings from Germany Manfred Under construction: Launch Pad 39A with Challenger STS-6 (1:144) |

|

#1406

|

|||

|

|||

|

You may have hit on it Manfred. I hope so. If not, your incredibly fertile mind will find the solution one way or another.

__________________

This is a great hobby for the retiree - interesting, time-consuming, rewarding - and about as inexpensive a hobby as you can find. Shamelessly stolen from a post by rockpaperscissor

|

|

#1407

|

|||

|

|||

|

Great stuff. Great to see your problem solving.Your attension to details is very inspiring to me.

|

|

#1408

|

||||

|

||||

|

Thanks elliott and bigpetr for your nice compliments.

Hello everybody, here briefly to the current state of the plumber works.  Today I have made a few longer half-pipes as a support for the first roundings of the longer gutters, by halving pipes (Ø 7.5 mm and Ø 6.0 mm) with the precision saw.  And in this way the roundings can be formed much more evenly and, above all, without larger dents or even kinks.    So it looks much better than yesterday,  and is still increasable, which makes me confident.  And as it looks so far, there could still be a happy ending with these gutters.

__________________

Greetings from Germany Manfred Under construction: Launch Pad 39A with Challenger STS-6 (1:144) |

|

#1409

|

||||

|

||||

|

Hello together,

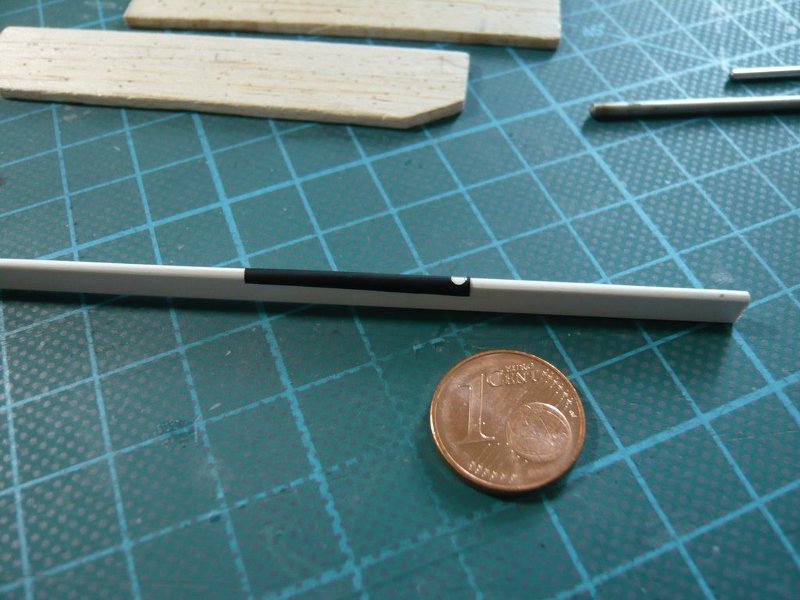

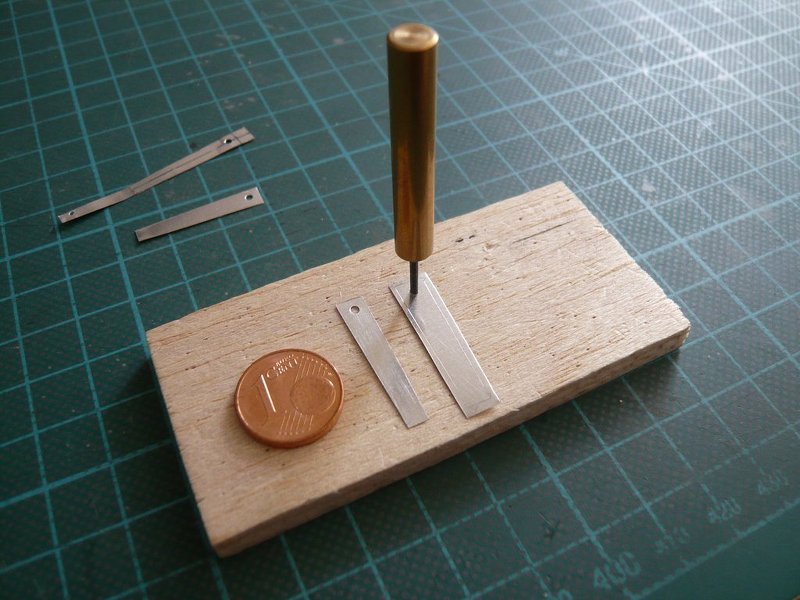

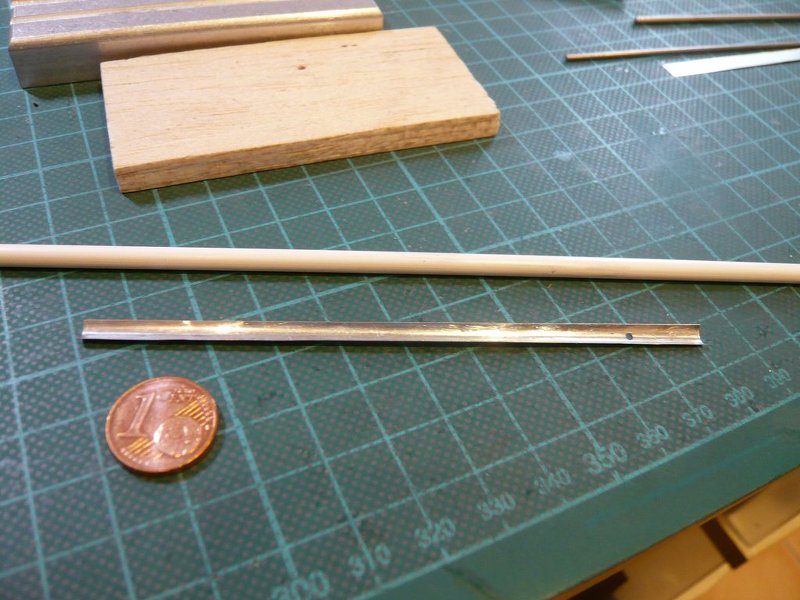

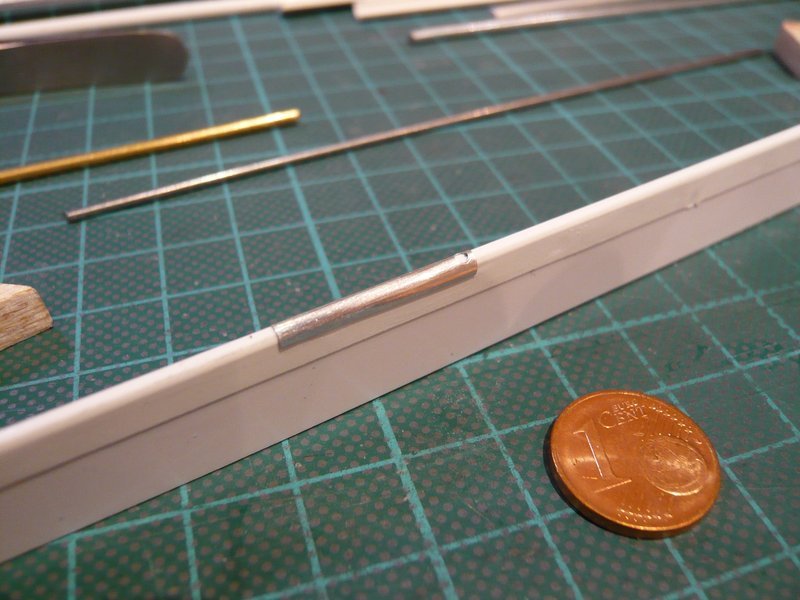

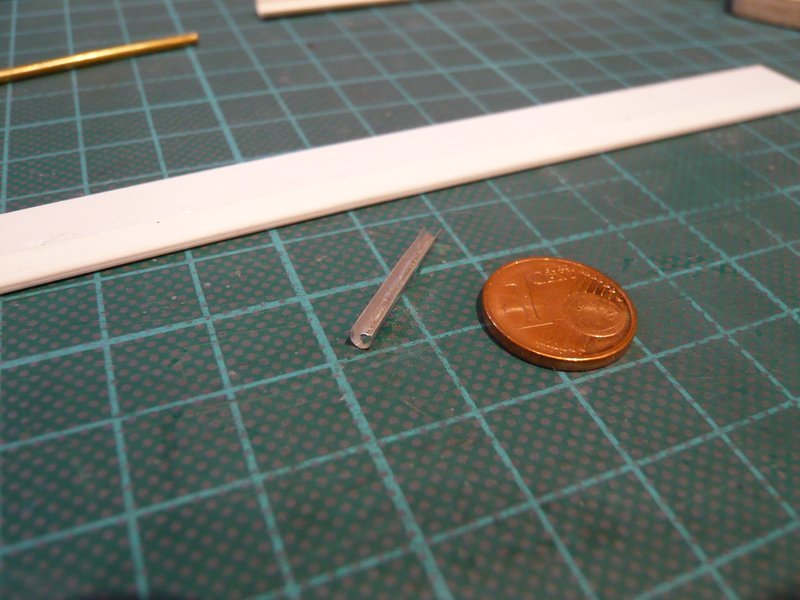

since I was still not satisfied with the last rounding step to the final gutter diameter of approx. 2.0 mm, I have tinkered at a better solution.  At first, I have made a few longer core wires for the longer half-pipes to get the curves evenly over the entire length.  With the last core wire of Ø 1,5 mm I get with the 0.1 mm aluminum sheet to approx. 1.7 mm, only I had to widen the gutter again and again, since the top edges are always rounding slightly again. With my previously used rectangular strip (1.5 mm x 5 mm), however, this did not achieve uniformly enough, especially with the longer gutters.  That is why I have sanded a 2 mm balsa board on one side down to a thickness of approx. 1.7 mm and rounded the edge in order to be able to widen the last rounding accordingly and to smooth it, which I have tested then at the end of the Gutter 1.   This may work in principle for short gutters, but is not a good solution for the longer gutters, since the Balsa board is too little stable in shape over the length and can partly be pressed in.  That is why I have choosen another, somewhat more complex, but more stable solution with a plastic strip. That is why I have choosen another, somewhat more complex, but more stable solution with a plastic strip.  But since there is no commercially available wider strips with about 1.7 mm thickness, I have made it myself.  For this purpose, I have cut a handy strip of 15 mm x 150 mm from 1.5 mm styrene and glued on both sides 5 mm wide strips of 0.1 mm Styrene, for which I used MEK, wherewith the composite strip is then approx 1.75 mm thick.  The more difficult part was then the smooth rounding of the edge, which took some time.  But with this core strip, it can be handled very cleverly by clamping the gutter into a Balsa "vise" to smooth it, without slipping or tilting.  And with this more sturdy plastic core, the desired half-round shape of the longer gutter should be doable reproducibly, which is very important.     And if this method now works as well with the longer gutters, which I assume, this would be great.

__________________

Greetings from Germany Manfred Under construction: Launch Pad 39A with Challenger STS-6 (1:144) |

|

#1410

|

||||

|

||||

|

Because it's emoji day,

|

|

|

|