|

|

#1621

|

||||

|

||||

|

Hi elliott,

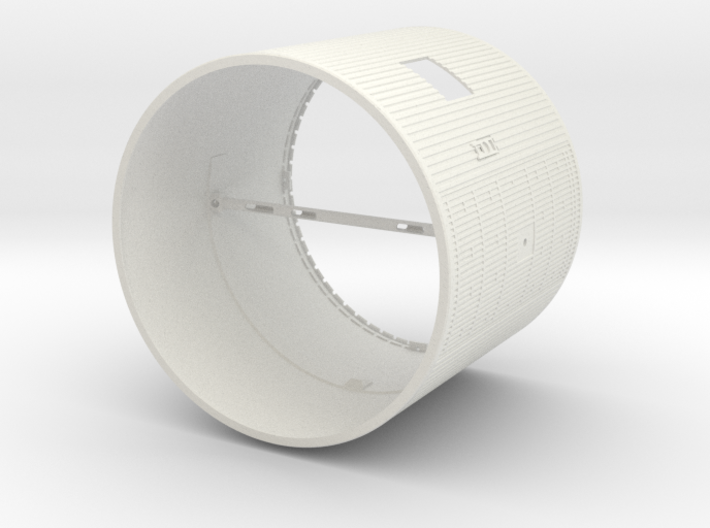

WSF stands for White Strong & Flexible and is another material for 3D printing, which is a white nylon plastic with a matte finish and a slight grainy surface.  Here is the 3D model of the IT by my friend Bill (niParts) from the ARC Forum, but unfortunately only in 1:72 scale.  Source: shapeways.com (niParts) But for 3D printing of finer details FUD (Frosted Ultra Detail) or even FXD (Frosted Extreme Detail) are used, but which are more expensive.  BTW, Shapeways is a well-known 3D print service provider, and offers also a Money Back Guarantee, which I have already benefited twice,  although that certainly should not be endless. But Michael Key and me feel really better with this version now and therefore I have just ordered it again. Therefore furthermore keeping all fingers crossed Guys that hopefully all good things will come in threes.

__________________

Greetings from Germany Manfred Under construction: Launch Pad 39A with Challenger STS-6 (1:144) |

|

#1622

|

||||

|

||||

|

Hello everybody,

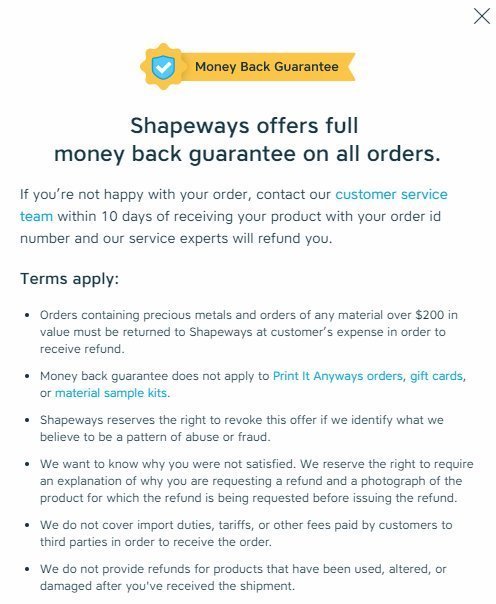

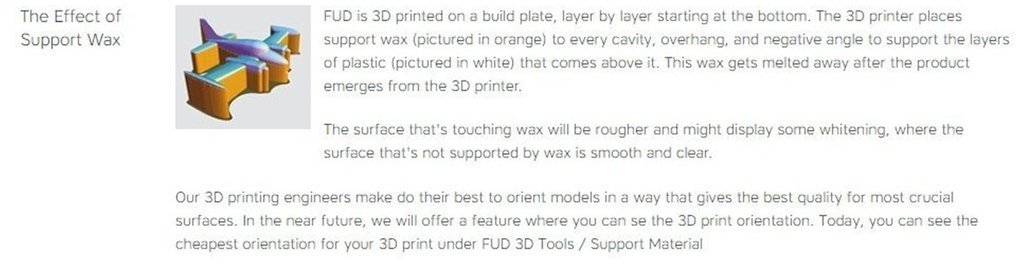

today with a short update from the Shapeways Team.  I just could not stand for this contradiction regarding the FUD tolerances  and I asked the friendly Shapeways lady, who initially wanted to give me only a lapidary, meaningless answer and I asked the friendly Shapeways lady, who initially wanted to give me only a lapidary, meaningless answer  , to explain this dilemma to me. , to explain this dilemma to me.  Thereupon was it confirmed by a production colleague that the maximum accuracy that SW can achieve at FUD is actually 0,4 mm, and that the SW guidelines should be adapted, to what one would now work on.  Well at least something for which my effort has been worthwhile, although still to this day one finds the unchanged previous precision specification of ± 0,1 - 0,2 mm for every 100 mm ...  Meanwhile, the third IT is on its way to me, and I'm curious what it will look like.  In the meantime, I've looked around a bit on the SW pages and now I can better imagine the matter with the Support wax, whereto I have found this nice image at the end of the FUD website with the following explanation.  Source: www.shapeways.com/materials/frosted-detail-plastic And remnants of this stuff one has still to remove off afterwards from the printed parts, although the cleaning at SW actually belongs to the standard procedure, but what is apparently not quite enough.  On this site you will also find an interesting Video in which the individual steps of the multi-stage production process are clearly presented by a SW production engineer.  After printing, the models are placed in a freezer to help detaching the parts, and then into an oven, where the wax base melts. Then they are placed first in an ultrasonic oil bath and subsequently in an ultrasonic water bath to remove residual wax and oil residues, and finally, after thorough water rinsing, they are dried and finally tested. Here is an image of the second IT, which looked a bit cleaner than the first one.  The traces of grease on the paper show, that remnants of the wax/oil remains for the customer unfortunately,    here during the sunbath of the two ITs for the allegedly necessary complete curing of uncured microscopic resin areas under UV light, which was proposed by a shapeways designer named Model Monkey, who is presenting some useful tips (FAQs) on how to use Shapeways prints.

__________________

Greetings from Germany Manfred Under construction: Launch Pad 39A with Challenger STS-6 (1:144) Last edited by spacerunner; 04-09-2018 at 07:18 AM. |

|

#1623

|

||||

|

||||

|

Hey everyone,

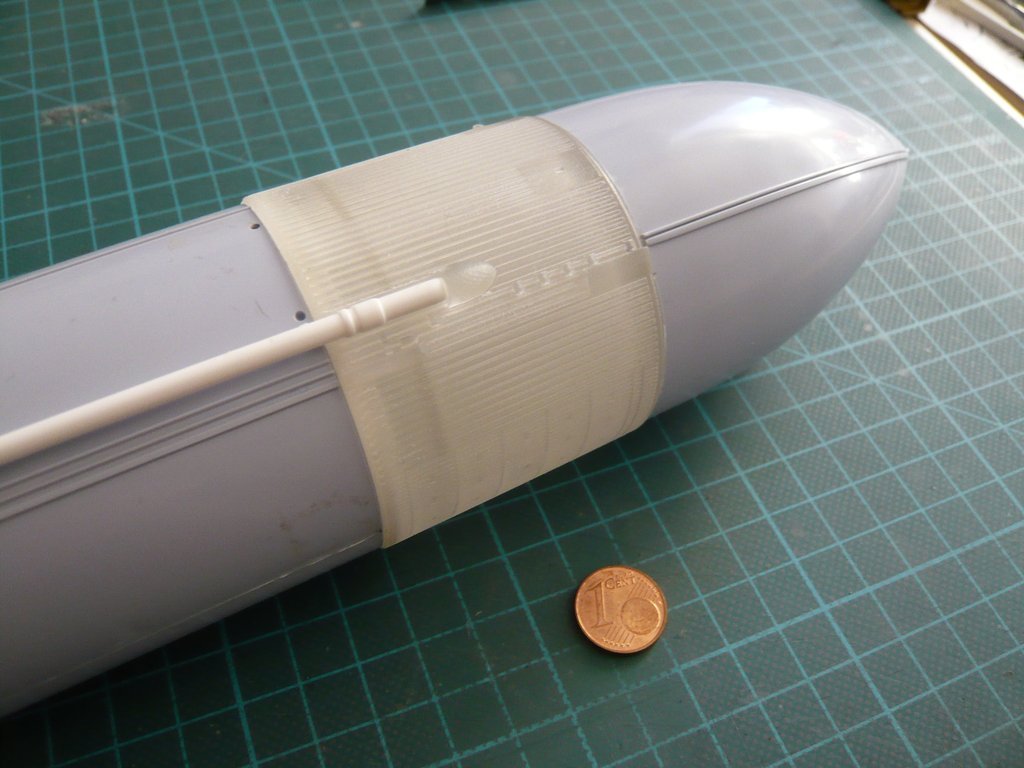

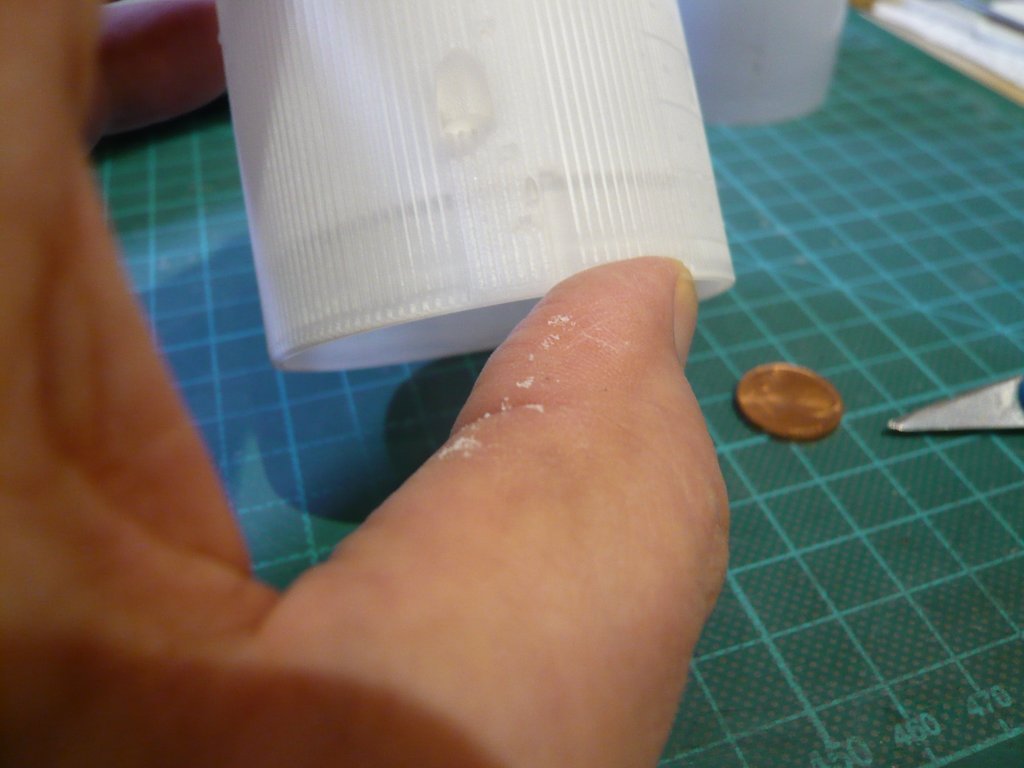

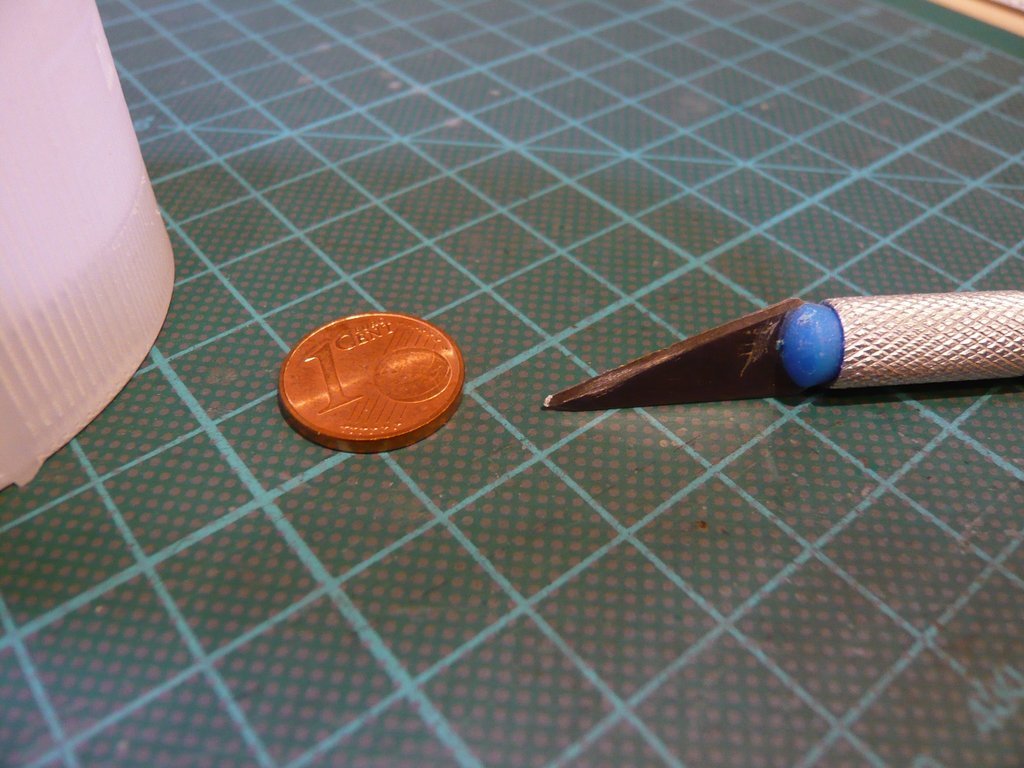

meanwhile, I have received the third IT, which makes a much better figure than the first two,  and fits also better between the two ET parts, as one can see here.    And here the LOX Feedline from the Revell Stack was laid down experimentally.   As my remeasurement has shown, but no shrinkage seems to have occurred, so one would probably get along without the 0.8% addition. Then I started with the tests for ultrasonic cleaning of the IT, for what I used the 2nd IT. To grope me step by step to the required cleaning time, I have each set the longest interval (600 sec.), which was repeated several times in succession.  First, I put the IT on the rear end and cleaned it in from this side a total of 30 minutes, with about 80% were immersed.    After this first cycle, the water looked rather cloudy,   and was therefore renewed for the cleaning of the other side, which then also took 30 min.. After that the IT looked like this, whereby one could see at a closer look but still wax residues in the grooves,  Therefore, I helped along with the electric toothbrush under running water, because the fine grooves between the stringers are obviously the purest wax catchers, which I had already feared.  But since even after this action still small wax remains were to be seen, then I grabbed the cutter and went on carefully further cleaning out the interspaces, which is also quite effective, as can be seen at the stripped off residues on my thumb,  as well as at the cutter tip.

__________________

Greetings from Germany Manfred Under construction: Launch Pad 39A with Challenger STS-6 (1:144) |

|

#1624

|

||||

|

||||

|

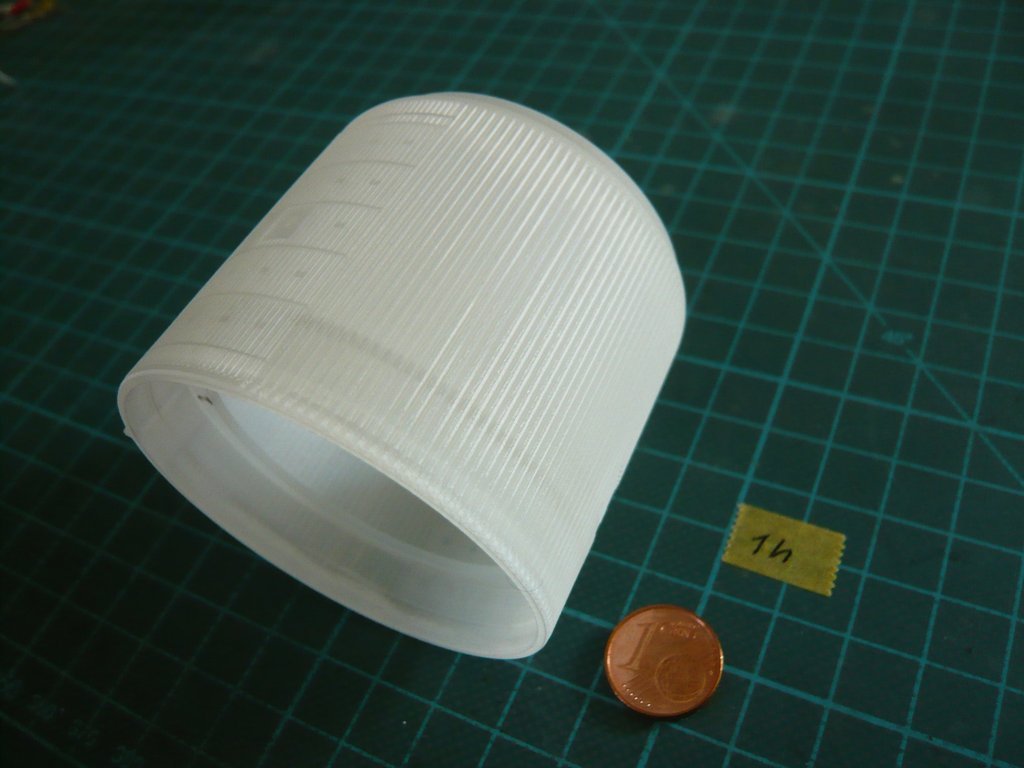

This stuff seems to sit so firmly in the grooves, so one will need much longer cleaning times in the ultrasonic bath, as initially suspected.

Therefore, I've added another pass of 30 min., which now gives a total cleaning time of 1 h, after which the water is always still cloudy.  But as one can see at these photos, there are still areas with more or less wax residue.     That immediately reminded me again of the 3-4 h cleaning time in the BANDELIN-Video during cleaning a FUD chain ...  So I will either extend the cleaning time still significantly, or sometimes have to try Aceton, or are there any ideas of the Shapeways experts here in the forum?

__________________

Greetings from Germany Manfred Under construction: Launch Pad 39A with Challenger STS-6 (1:144) |

|

#1625

|

|||

|

|||

|

Looking promising for this third 3d printed part from shapeways. Fingers crossed it is okay when fully cleaned.

I am sure this has been quite a stressful time for you with shapeways. Hope you are feeling more confident now Manfred. Regards Kevin

__________________

Normally the most advanced tech I use is a pencil. |

|

#1626

|

||||

|

||||

|

Hi Kevin,

oh yeah, that was really a tough job and a stressful time but not only with Shapeways, but rather also with my designer Michael Key during the tricky modeling process until we had clarified all the details and problems.  But now we can be proud of the result and recommend it to all who are interested in this cool IT.  All I have to do now is to clench my teeth to get a handle on the cleansing of the IT with its seemingly 1.000 grooves,  what is a rather tough nut to crack. what is a rather tough nut to crack.  But step by step, I am moving forward to break through these obstacles too ...

__________________

Greetings from Germany Manfred Under construction: Launch Pad 39A with Challenger STS-6 (1:144) |

|

#1627

|

|||

|

|||

|

Are you using water in your ultrasonic cleaner Manfred? Did Shapeways recommend any type of cleaning solution? You might want to try a very dilute solution of a household cleaner (don't know what you have in Germany). Just a thought.

__________________

This is a great hobby for the retiree - interesting, time-consuming, rewarding - and about as inexpensive a hobby as you can find. Shamelessly stolen from a post by rockpaperscissor

|

|

#1628

|

||||

|

||||

|

Hi elliott,

yep, I'm using lukewarm water with a dash of dishwasher detergent.  But maybe I should take hot water and a little more dishwasher detergent, especially since FUD is heat resistant up to 80 degrees. Slowly, I feel like an alchemist in his witches' kitchen.  BTW, here is a more vivid video Cleaning Process Comparison: MJM vs PolyJet about the whole sequence of treatment steps of MJM Shapeways prints.

__________________

Greetings from Germany Manfred Under construction: Launch Pad 39A with Challenger STS-6 (1:144) |

|

#1629

|

|||

|

|||

|

Hi Manfred

This is just a thought, but if all else fails you could try putting the IT fully submersed in a solution of warm water with a few drops of washing up liquid and leave it overnight , 8 to 10 hours say. This should give time for the detergent to get into the bond between the wax and the IT material. Then put it straight into the ultra-sonic cleaner first thing in the morning. (This sort of "long pre-soak" method is used in industry for quite a number of cleaning processes). Please note however I have never done this myself on a 3d printed object. Only done it for metal/glass/plastic objects Regards Kevin

__________________

Normally the most advanced tech I use is a pencil. |

|

#1630

|

||||

|

||||

|

Hi Kevin,

and thanks for your cool proposal, which seems to be more than only a thought.  Maybe I should try that too.  BTW, during looking at the second part of the video I just got a very daring idea ...   Maybe I should held the part under my Kärcher Spray Gun ...

__________________

Greetings from Germany Manfred Under construction: Launch Pad 39A with Challenger STS-6 (1:144) |

|

|

|