Hello Guys,

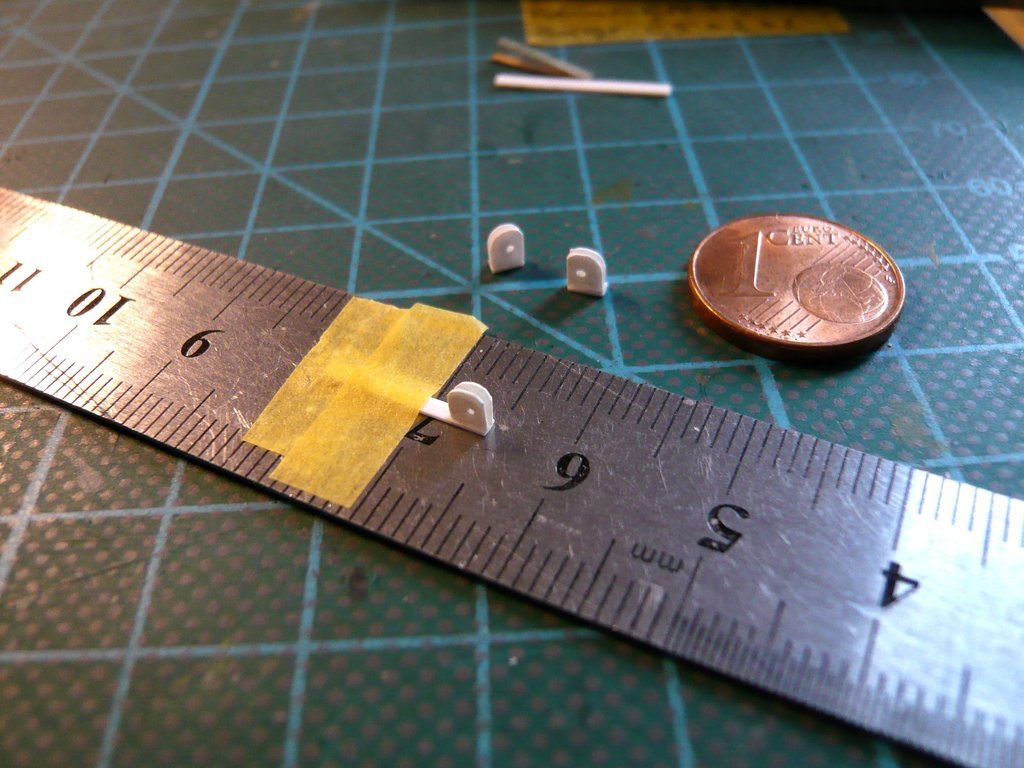

after I did successfully scratch the first

Hold-down clevis quite well, I've glued the remaining three clevises together too.

Because the simultaneous gluing of the plates with

MEK proved to be too unstable due to the minimal adhesive edges, I proceeded a little differently this time and used my steady hand and my eagle eyes trusted.

This time I fixed the

base plate strip (1,3 m) to a steel ruler so that nothing could slip. Then I wet a

Clevis plate lightly on the lower edge with

Revell glue and carefully close to the edge of the strip (approx. 0,2 mm) placed at its end. After that, there was still enough time for the finest position corrections.

I then glued the other plate in the same way, inserted a spacer strip the thickness of the

Tie-down Lug Plate (0,4 mm) between the plates and gently pressed both together with the tweezers. Then the position of the plates was adjusted to each other and the central position of the pair of plates was checked and adjusted if necessary, which worked quite well.

After that, to be on the safe side, I brushed the glued areas of both plates with

MEK and cut off the base plate strip flush,

and the second Clevis was done too.

The two remaining Clevises then followed in the same way.

And as one can see, the

Tie-down Lug Plate still fits in between, which was my biggest concern at first.

Next I tackled the two

stoppers that one can see in this image on either side of the bottom of the canister. In my opinion these are more likely to be

Sliding shoes for the

Payload Canister, through which is guaranteed a certain guidance of the canister when the canister is set down on the

Transporter as well as during unloading and hoisting into the

RSS-Payload Bay.

Source: wikimedia.org (STS-132)

Source: wikimedia.org (STS-132)

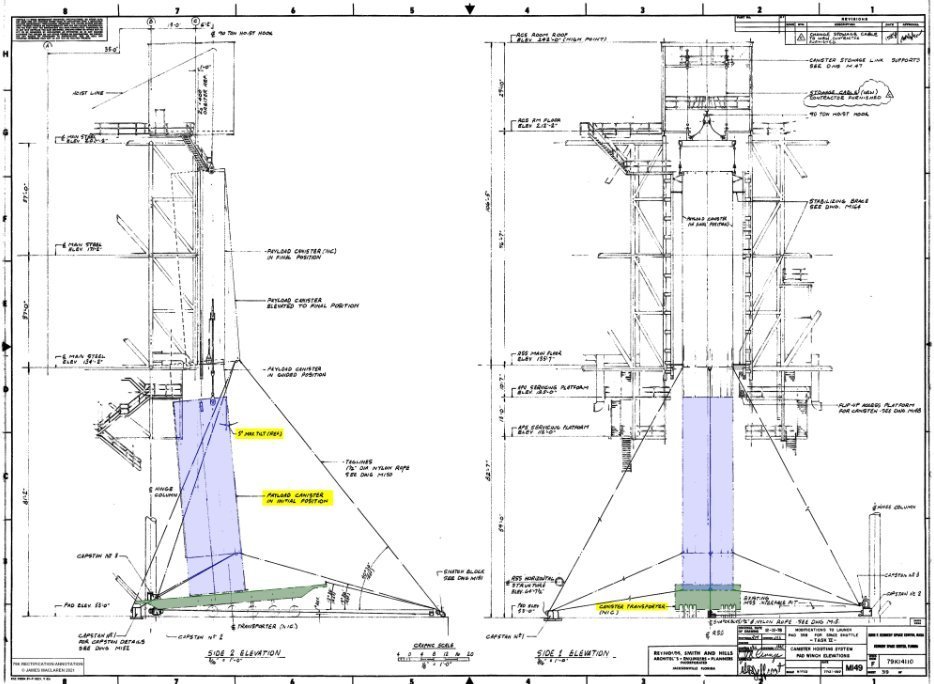

The fact that this

PLC-Hoisting is an extremely complicated and not without danger process, I was just reading in

James MacLaren's Page 51 on the

Canister Hoisting System in his treatise about the structure of the

Launch Complex 39-B, what I can warmly recommend to all interested parties,

which made a lot of things clearer to me, such as the need for additional securing of the canister on the

"kneeling" transporter with several

Tethers (Tag lines) during the Canister is hanging on the crane hook.

Source: James MacLaren - The Construction of Space Shuttle Launch Complex 39-B (Page 51)

Source: James MacLaren - The Construction of Space Shuttle Launch Complex 39-B (Page 51)

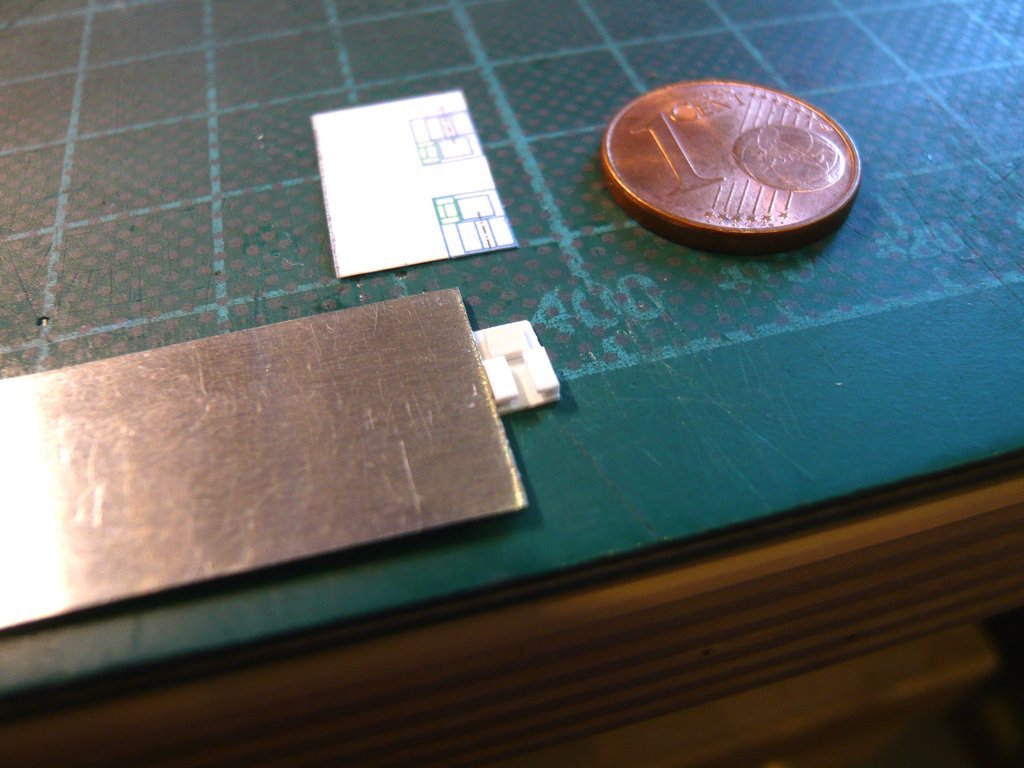

The sliding shoes sit on

base plates, which are screwed onto the smaller

Transportation Support Plates of the transporter during the

Vertical Transportation mode.

For the base plate I used an

Evergreen strip (0,75 mm x 1,5 mm), which I filed down to a

width of 1,2 mm and cropped to

2,4 mm length.

For the sliding shoe, I filed an

Evergreen strip (1,5 mm x 1,5 mm) to

1,2 mm x 1,3 mm, which was cropped to

3,5 mm length.

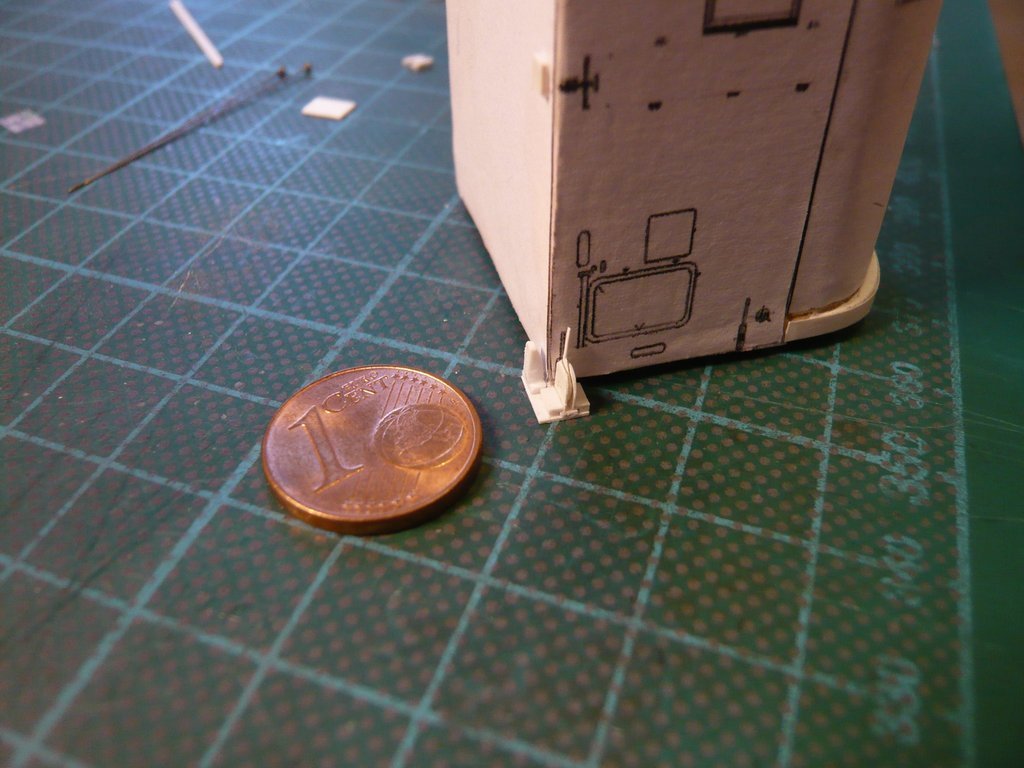

Then I wanted to do a first

vertical test fitting of the canister on this transport plate and I have glued on the

PLC base plate (0,5 mm x 2 mm x 2 mm) as a support for the canister,

have temporarily put the base plate of the sliding shoe on and set up the canister, what fits together quite well.

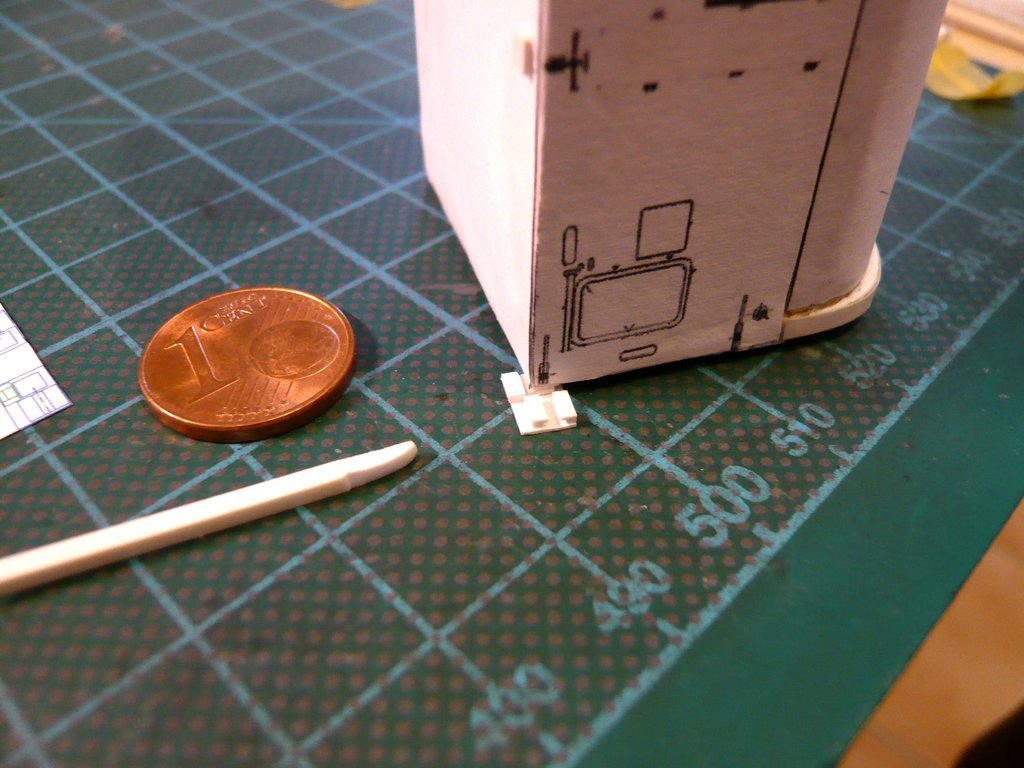

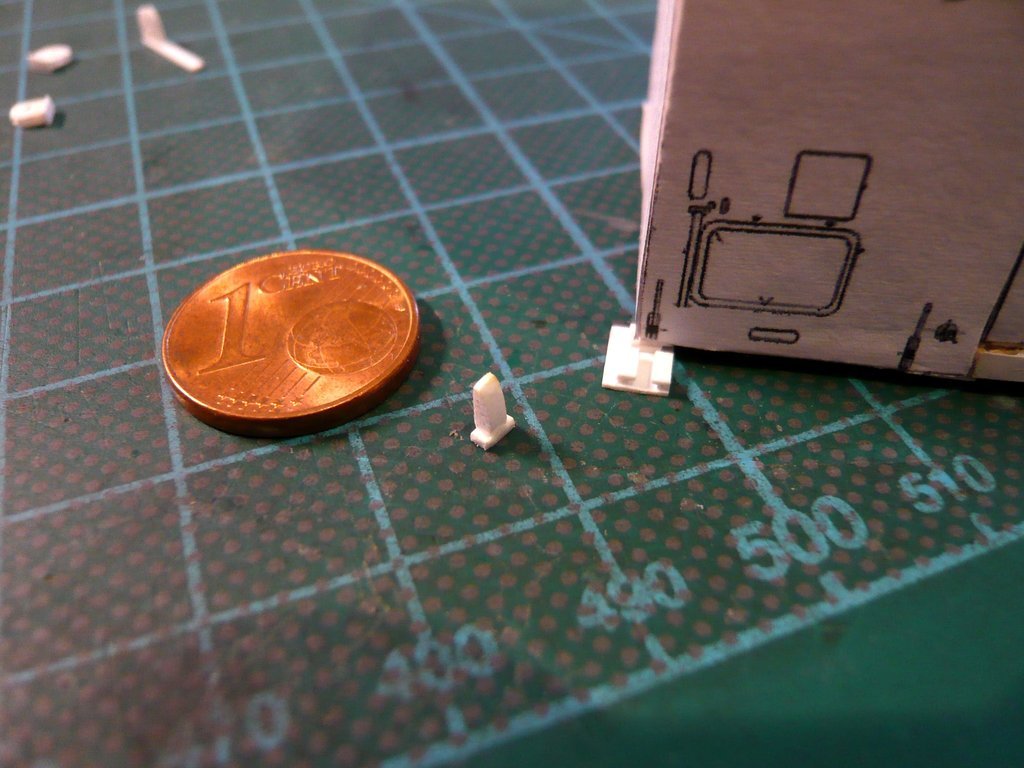

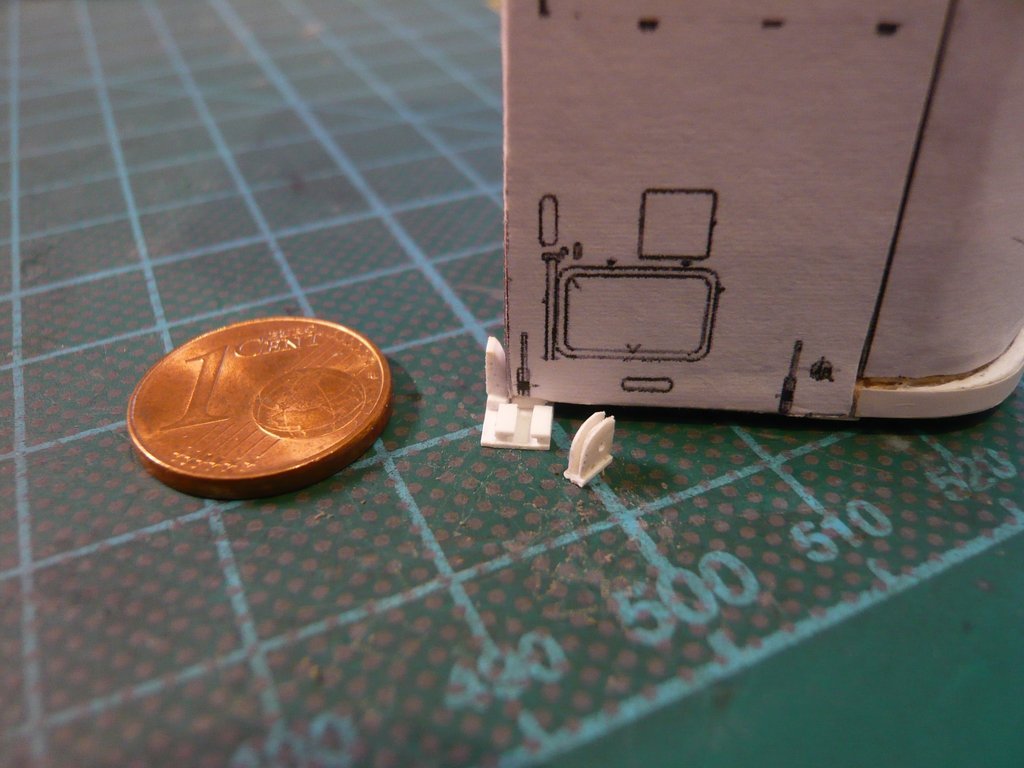

And this is what the finished sliding shoe looks like,

which is here standing on the plate, in front of it the

Clevis is standing already,

which is inserted here with the inserted

Lug Plate in the brackets,

but what is hardly recognizable from this distance.

The same Transportation support plate now will follow for the other corner, and then the two larger Transportation support plates will follow.