|

|

#2431

|

||||

|

||||

|

I hope this is a compliment, Becky.

__________________

Greetings from Germany Manfred Under construction: Launch Pad 39A with Challenger STS-6 (1:144) |

|

#2432

|

||||

|

||||

|

Hello friends,

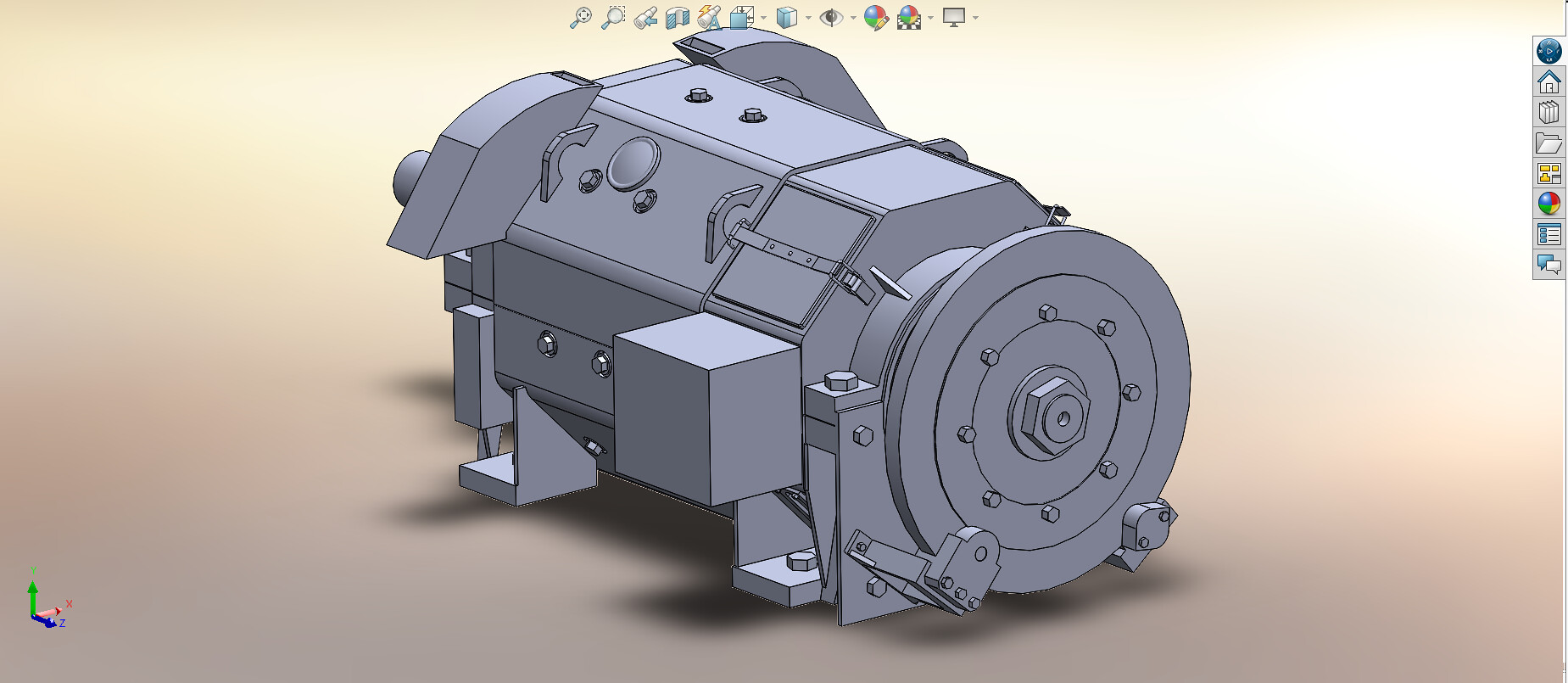

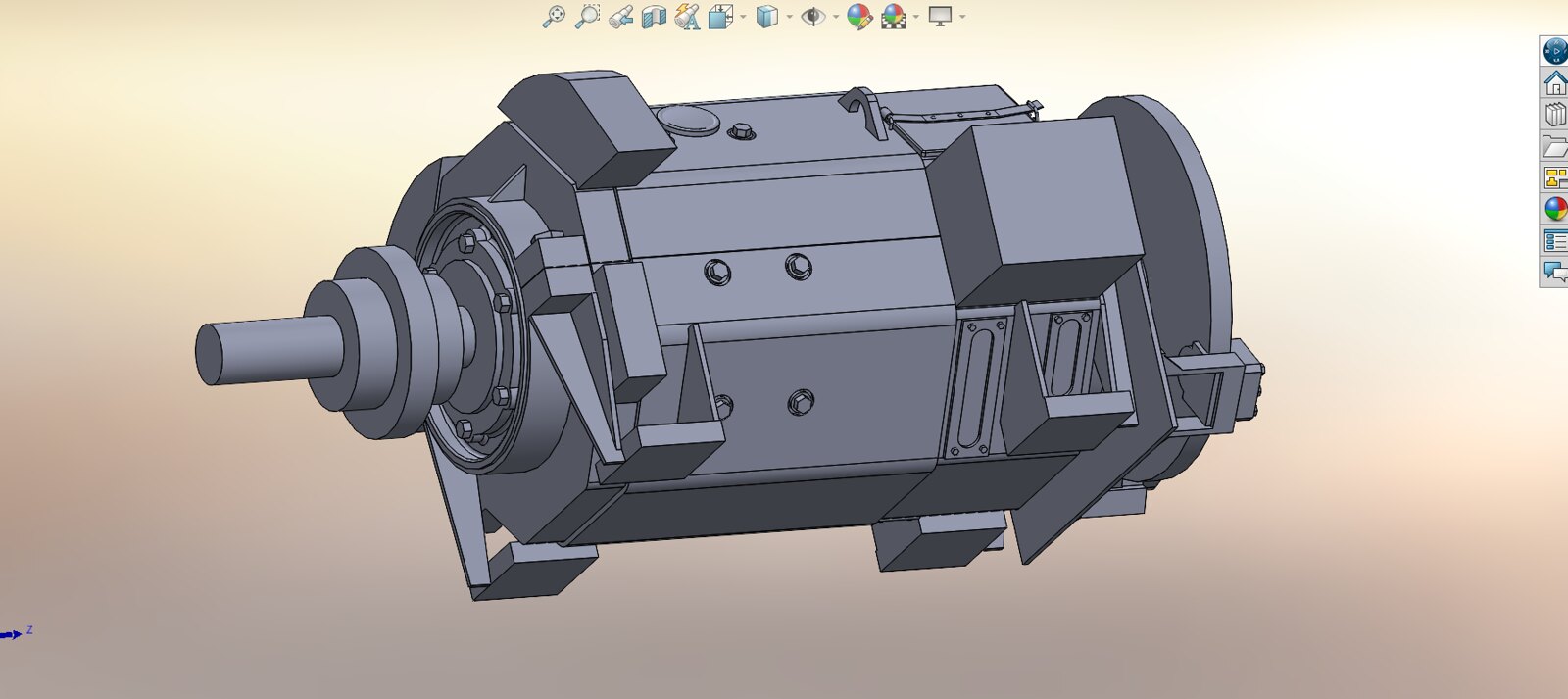

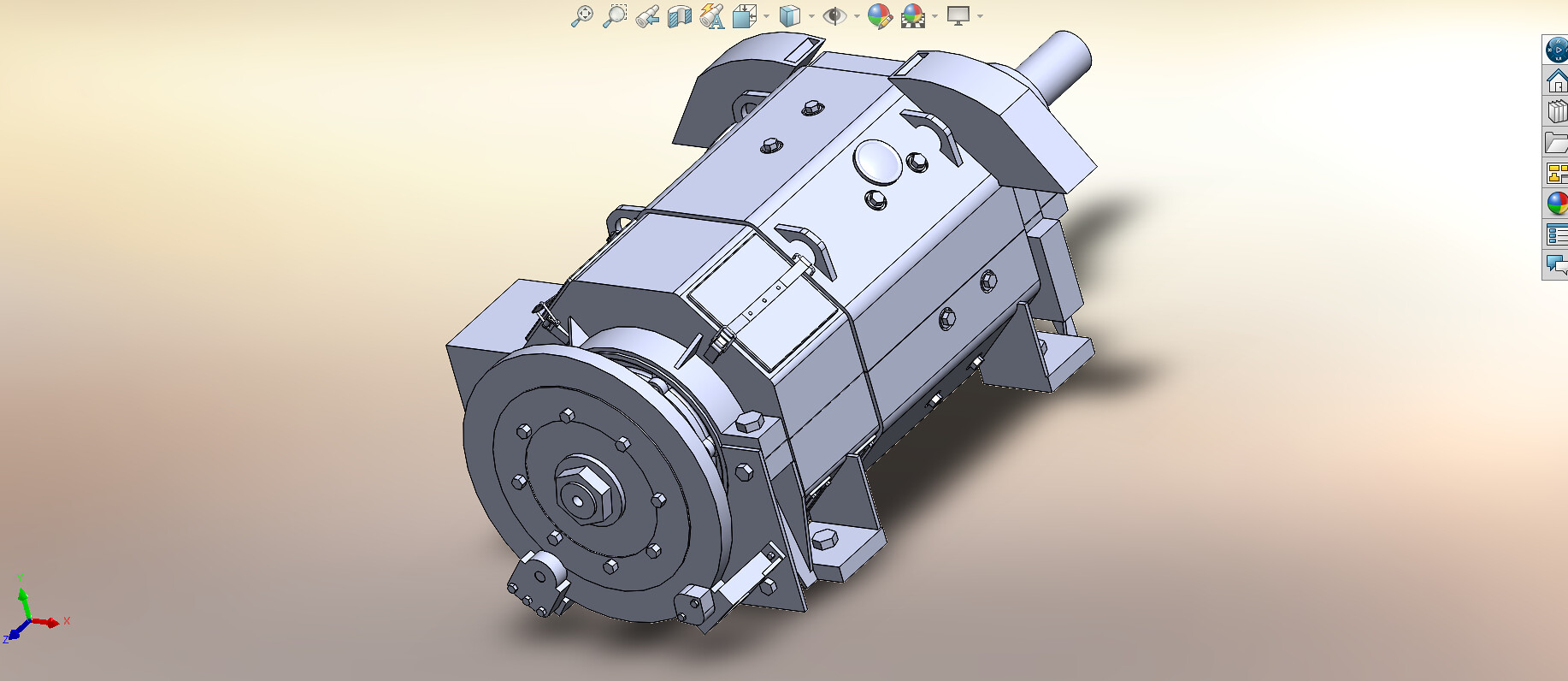

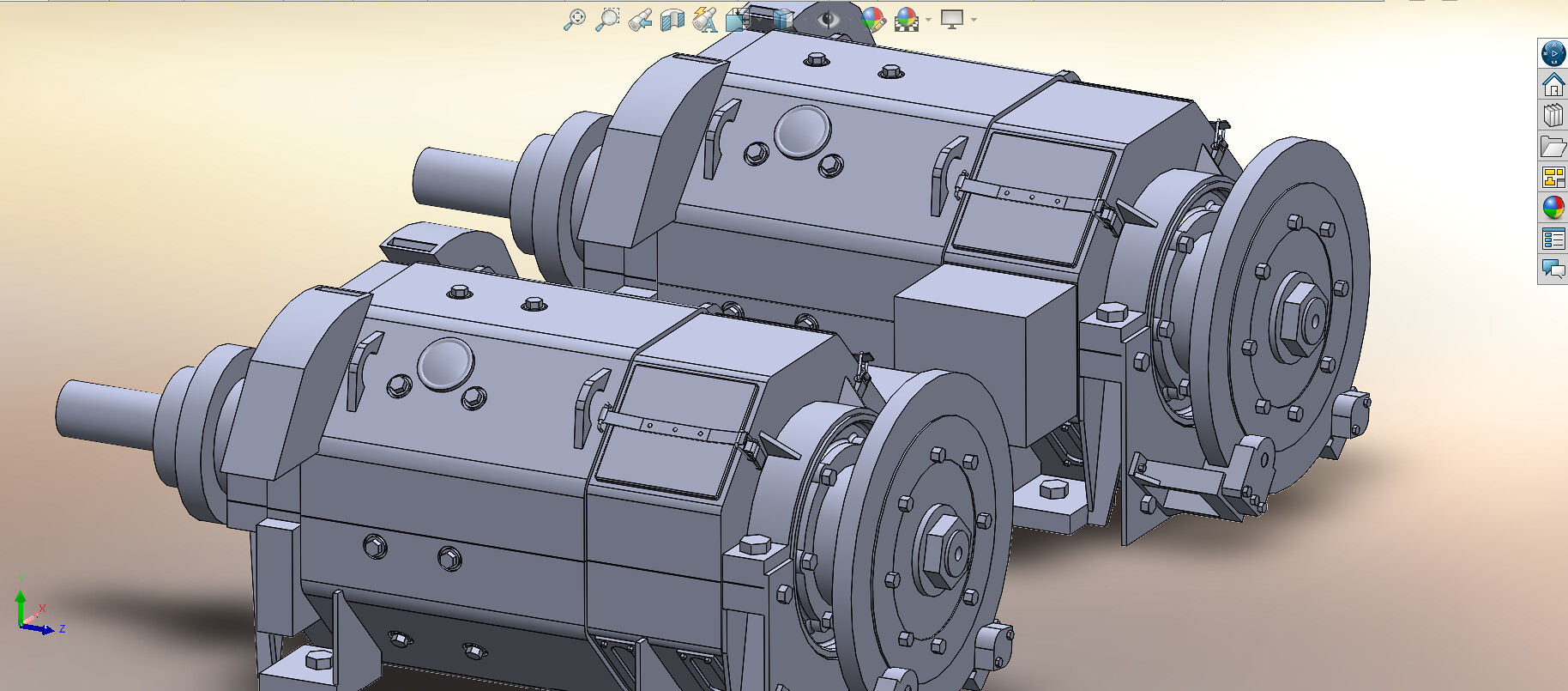

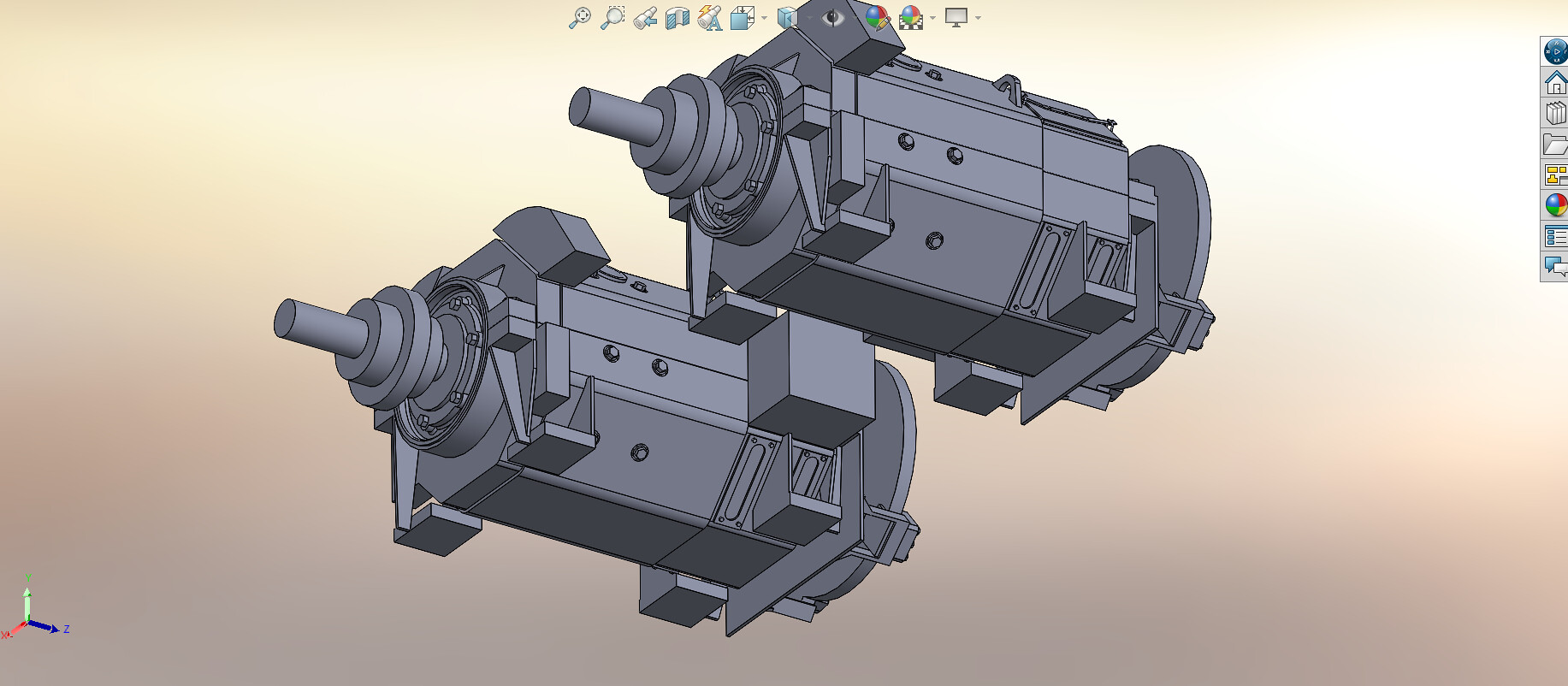

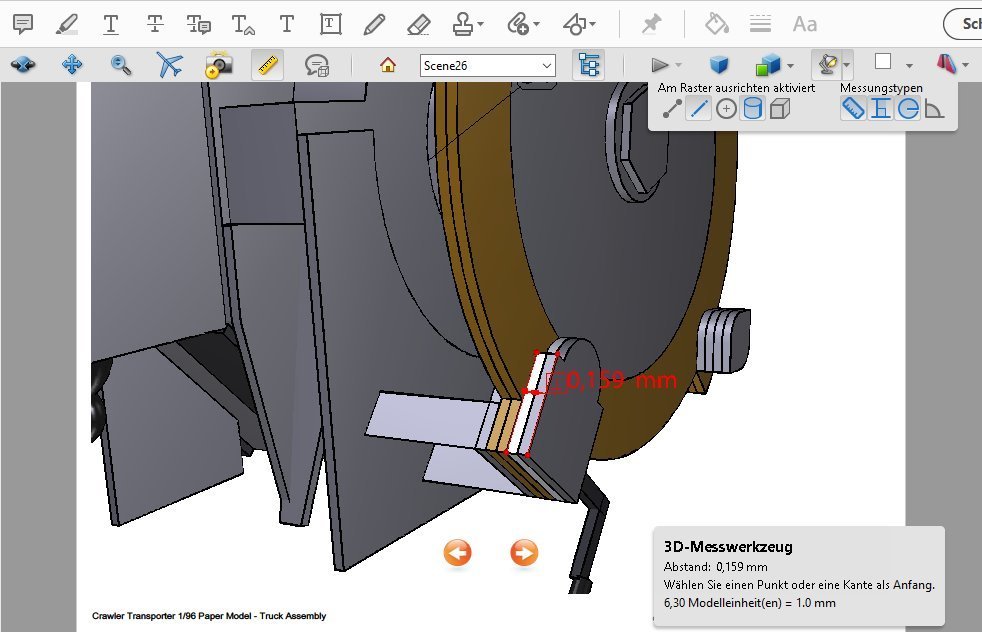

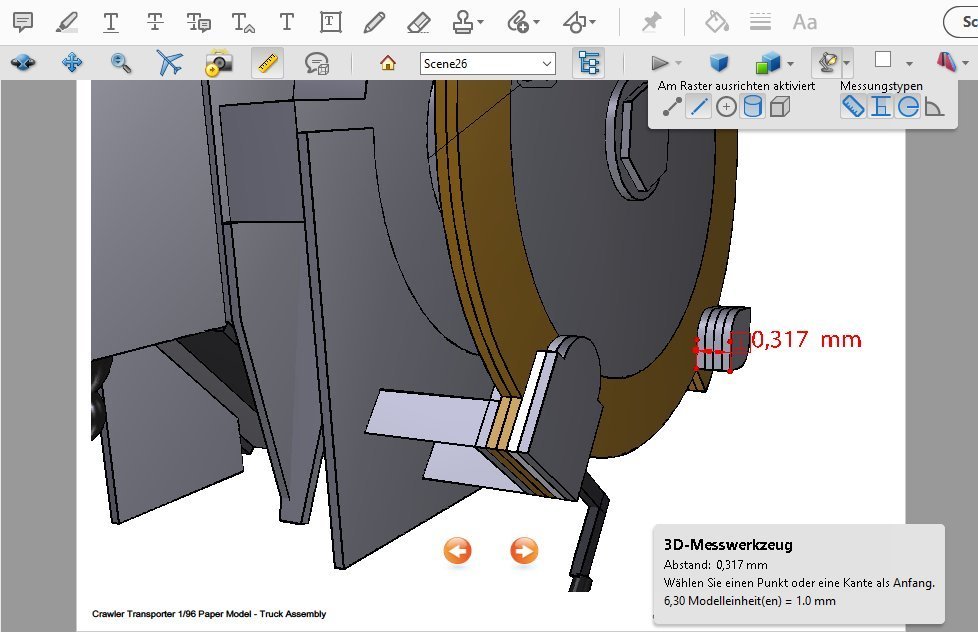

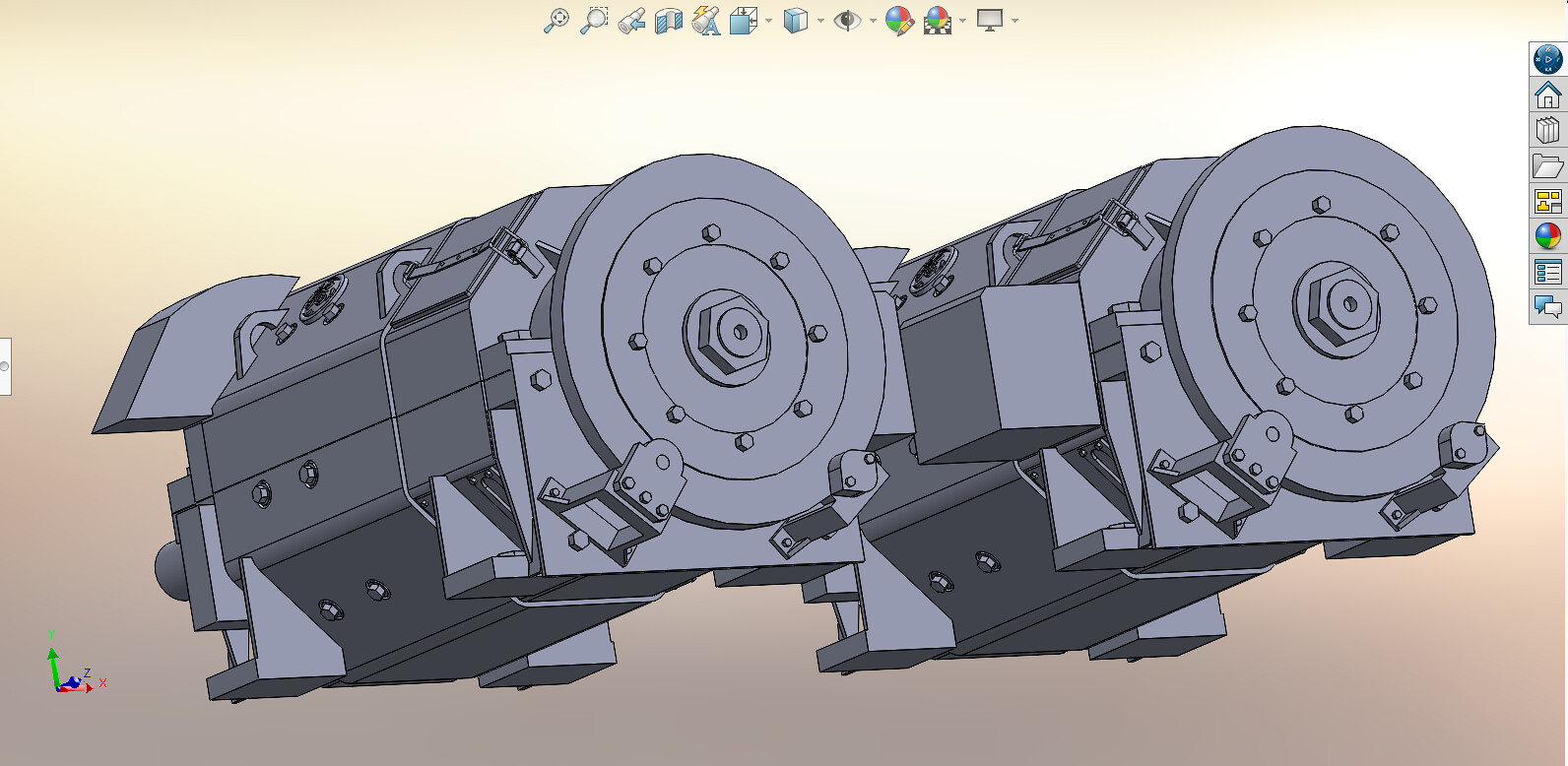

while I was agonizing over this tiny motor, my ARC friend (crackerjazz) was busy modeling and has sent new progress shots with more details, which look great.  As one can see, he even got right the Toggle fastener on the Flaps over the service openings,  although some details, like this one, may need to be simplified or enlarged in order to be printed. although some details, like this one, may need to be simplified or enlarged in order to be printed.   These images all show the left Propel motor in different perspectives.     This also includes a right motor, since they are always arranged in pairs, as has already been seen several times.  Source: NASA And this right motor is now also modeled, so the set is complete. Heart, what more do you want!    I have already thanked the creator warmly for this, However, I've noticed a little detail that I've told him with the request for correction. And that concerns the two brake shoes, which have the same thickness in the present model, but of which the larger brake shoe is actually only half as thick as the smaller one, as one can see in these 3D PDF images and also in the original photo. The multiple layers in the paper kit always correspond to a paper thickness of approx. 0,1 mm.  Source: Micro Artwork, Mischa Klement (cyana)  Source: Micro Artwork, Mischa Klement (cyana) Therefore the Brake disc should only be approx. 0,2 mm , for which as a matter of prudence he has chosen 0,3 mm in his 3D model, as this is according to the Shapeways-Design Guidelines is the minimum wall thickness for a supported wall, which is connected at least on two sides of the wall, while an unsupported wall (minimum 0,6 mm!) is connected only on one side of the wall, which is why some parts, whose thickness in the model previously only corresponds to the paper thickness, still have to be modified.  Fortunately, the brake disc is connected on three places, namely with the drive shaft and with the two Brake shoe holders, which is why a thickness of 0,3 mm should be permissible in my opinion.

__________________

Greetings from Germany Manfred Under construction: Launch Pad 39A with Challenger STS-6 (1:144) |

|

#2433

|

||||

|

||||

|

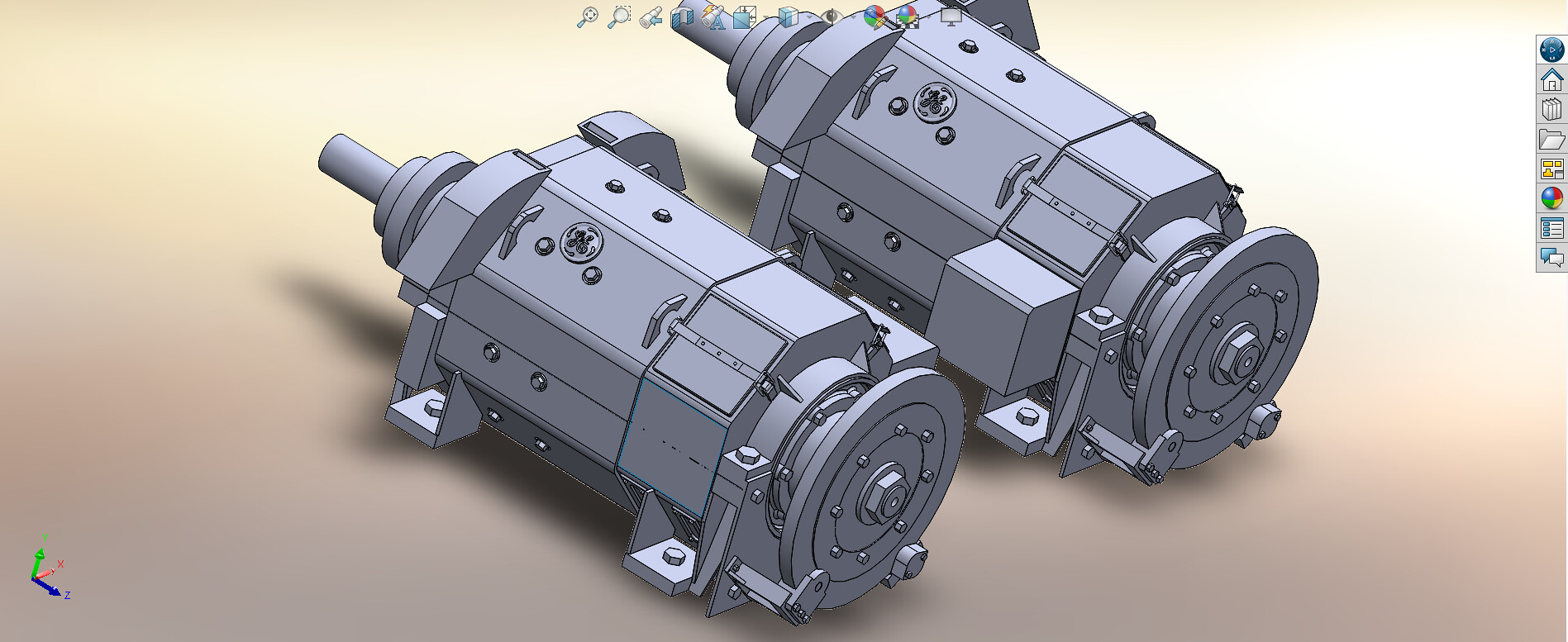

Hello everybody,

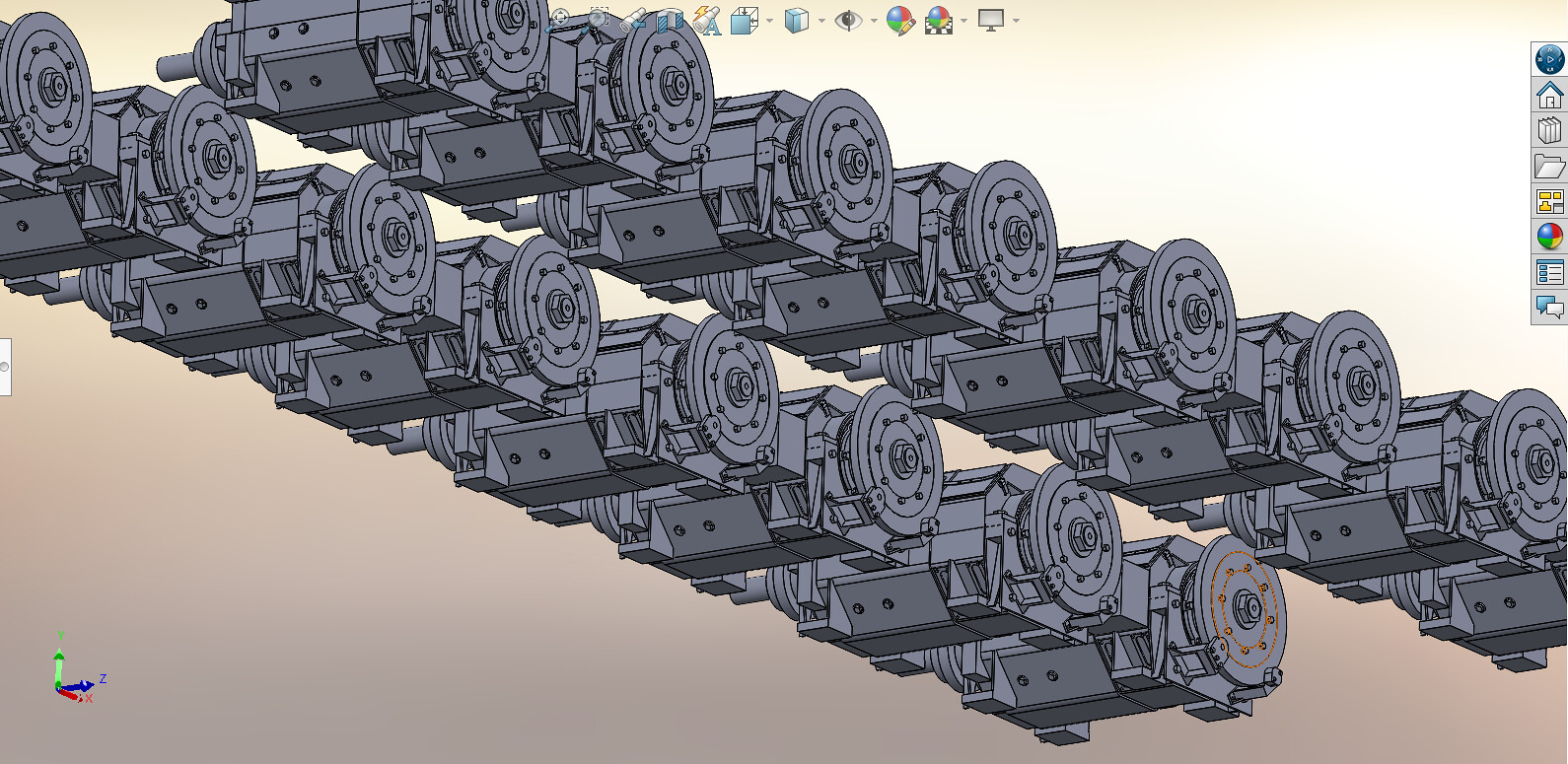

in the meantime, my Ghostdesigner has also taken into account twice the thickness of the smaller brake shoes in his 3D model, wherewith the picture always more is rounding off itself.       And this is a look ahead to the later Propel Motor Set, which Shapeways could then print once the adjustments have been made. In addition, the connecting webs between the motor rows have to be modeled before the complete set can be uploaded to SW.    In these theoretical Sets of 16 motors the adjustment/enlargement of the details is not yet taken into account, but this will happen soon. In addition, in the final set, at least 2 reserve motors should be provided in order to have a backup.  Next I will turn to the Gear cases, of which, logically, 16 pieces are also required, which also is craving for 3D printing.  Source: Micro Artwork, Mischa Klement (cyana) After all, the motor power has to come onto the Crawler chains and from there onto the Crawlerway.

__________________

Greetings from Germany Manfred Under construction: Launch Pad 39A with Challenger STS-6 (1:144) |

|

#2434

|

|||

|

|||

|

Herr Manfred!!

I bow down to your greatness!!

|

|

#2435

|

||||

|

||||

|

Your ability to work with micro sized parts always leaves me speaking in tongues!

|

|

#2436

|

||||

|

||||

|

Then I had the right guess, your luck Becky!

__________________

Greetings from Germany Manfred Under construction: Launch Pad 39A with Challenger STS-6 (1:144) |

|

#2437

|

||||

|

||||

|

Hello everybody,

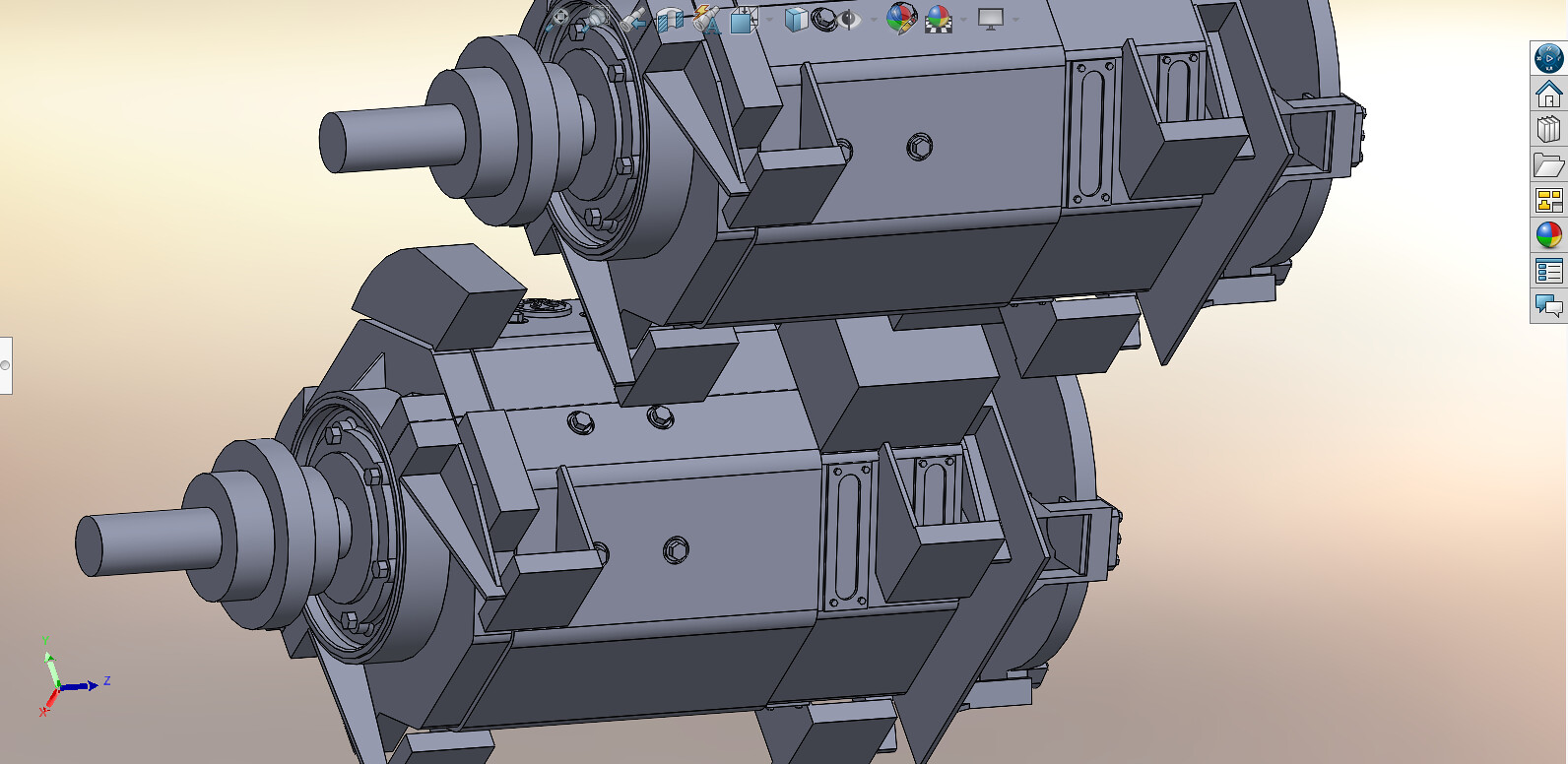

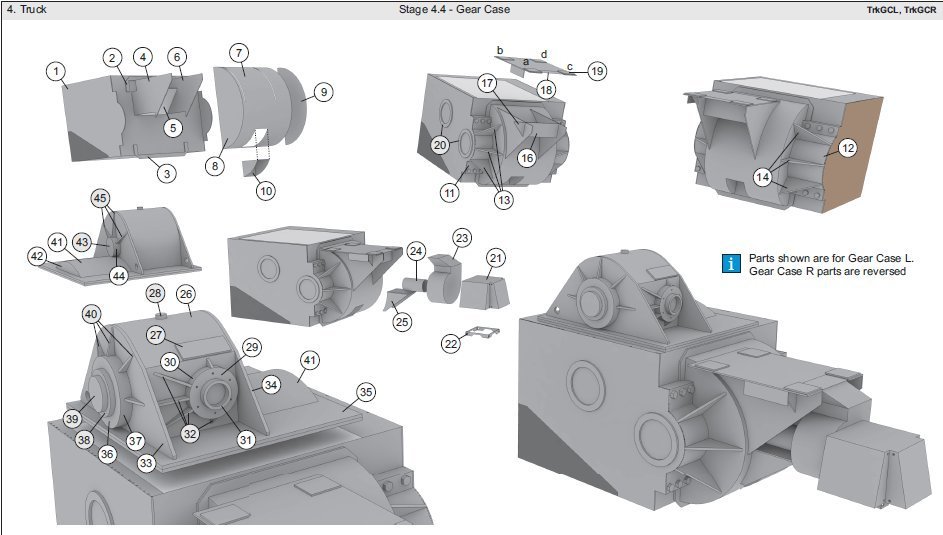

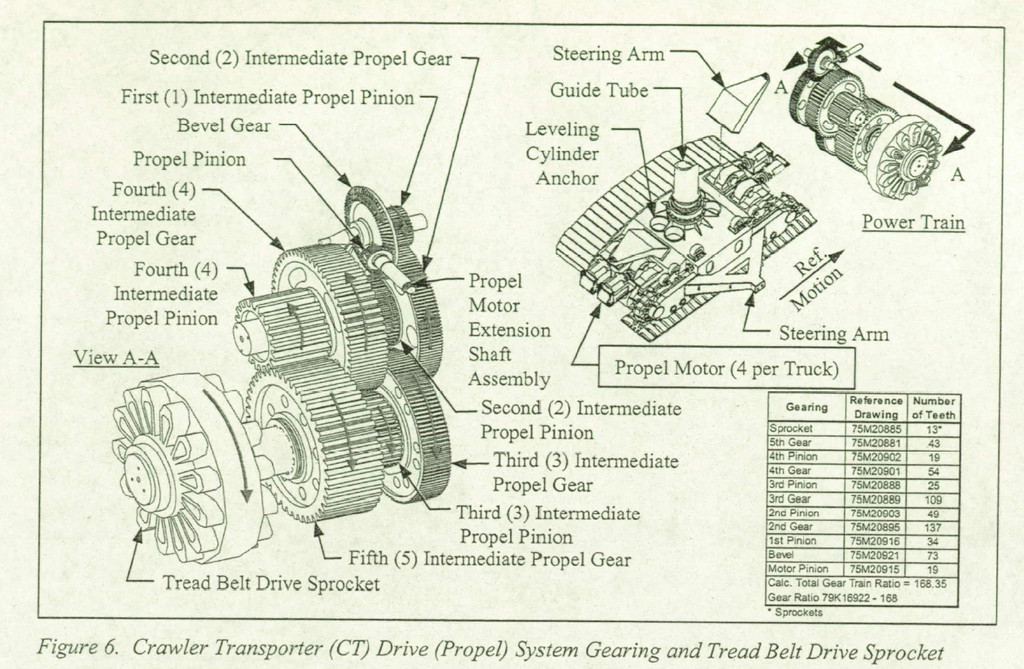

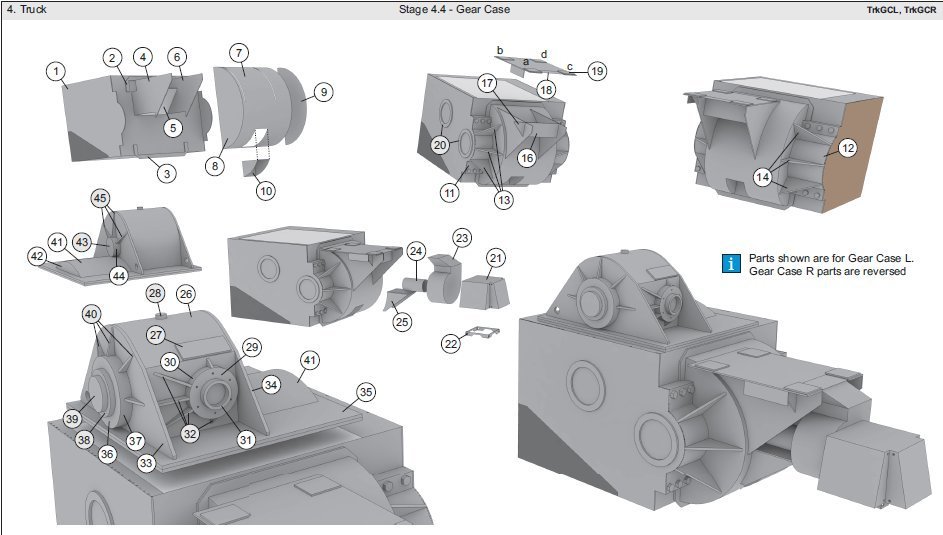

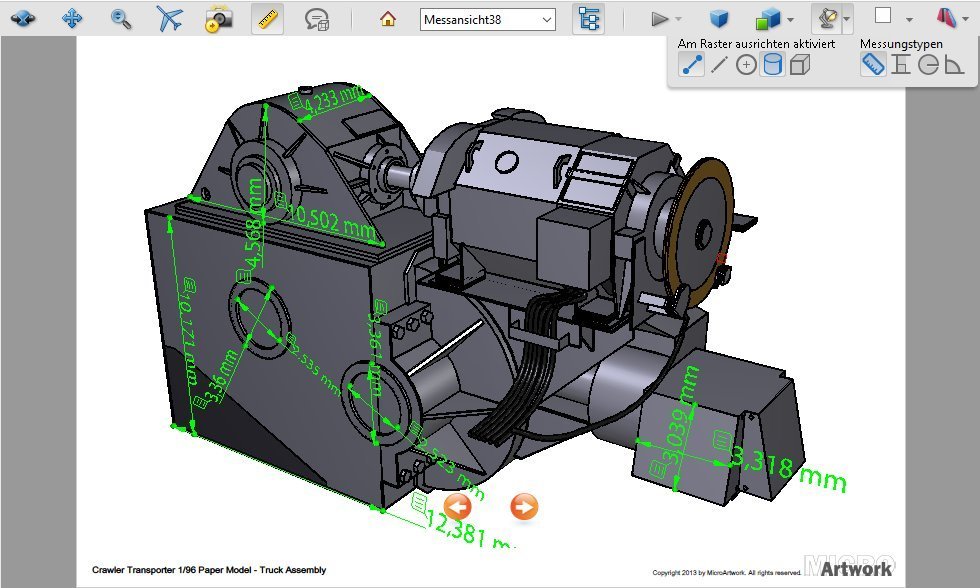

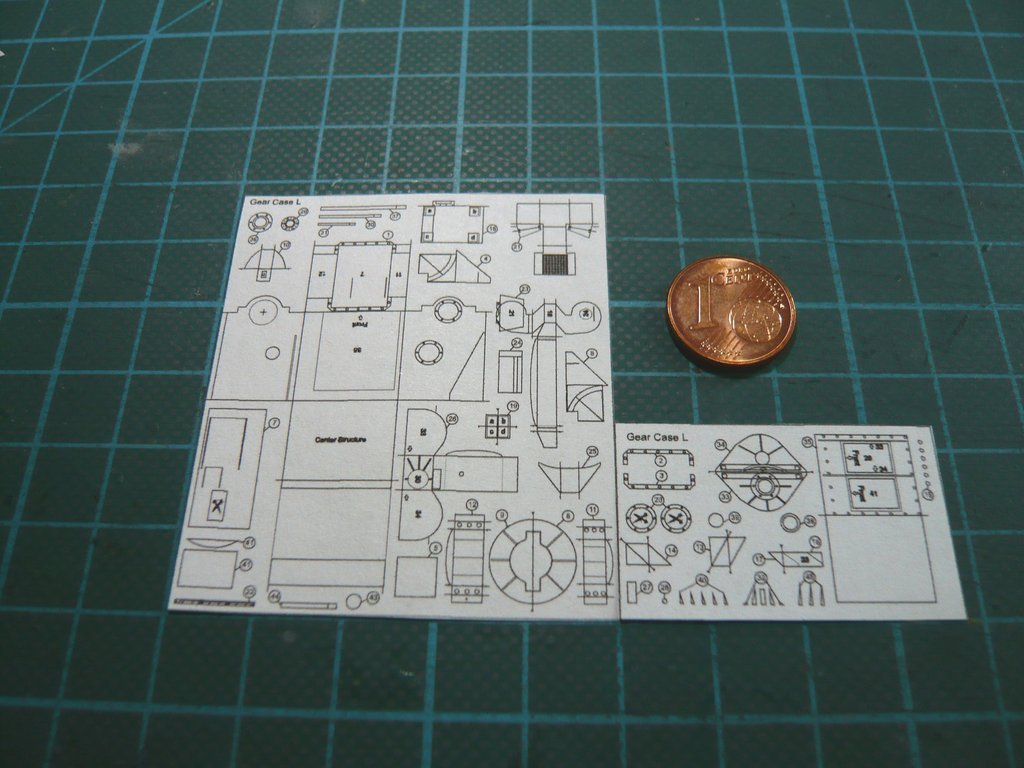

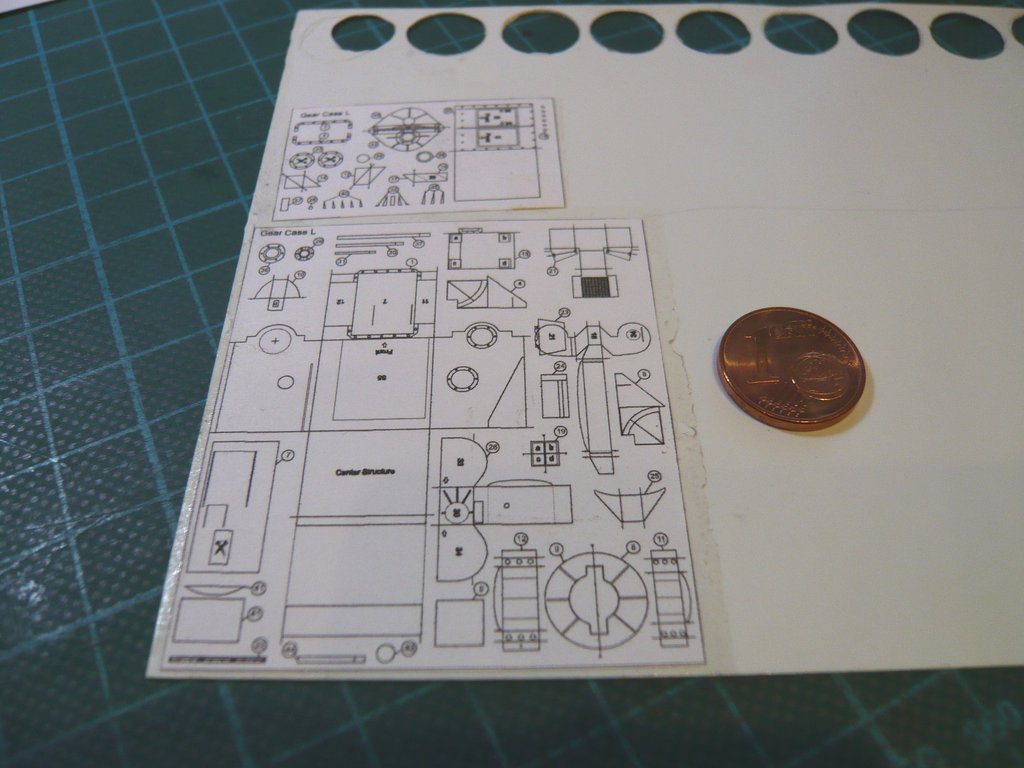

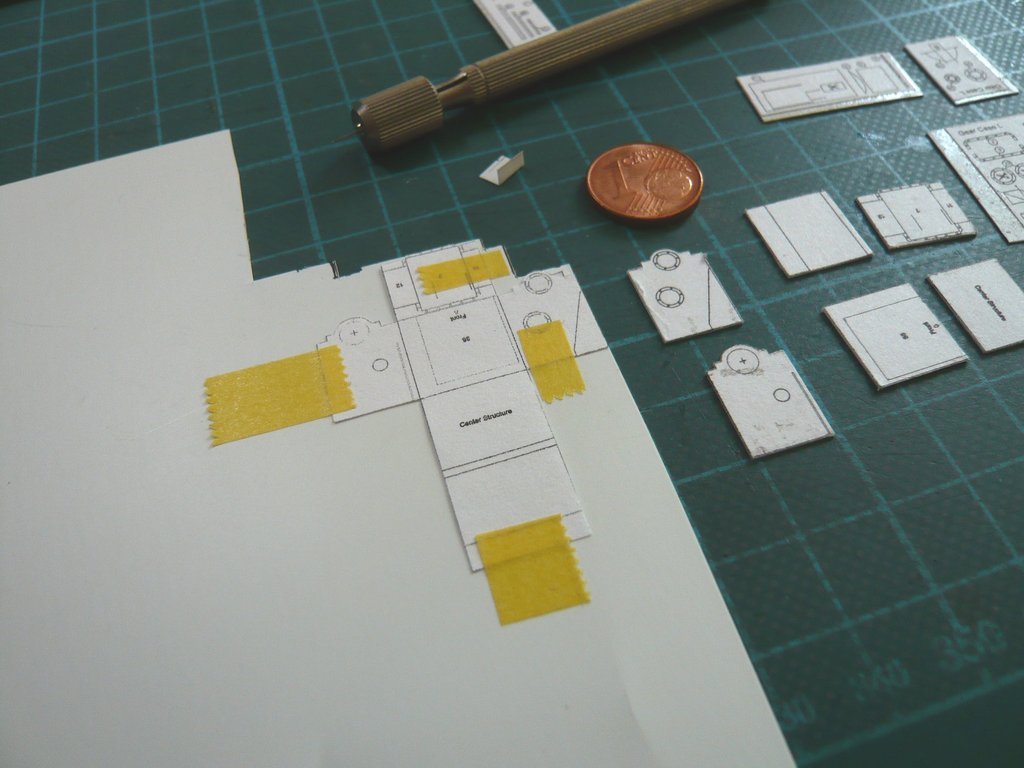

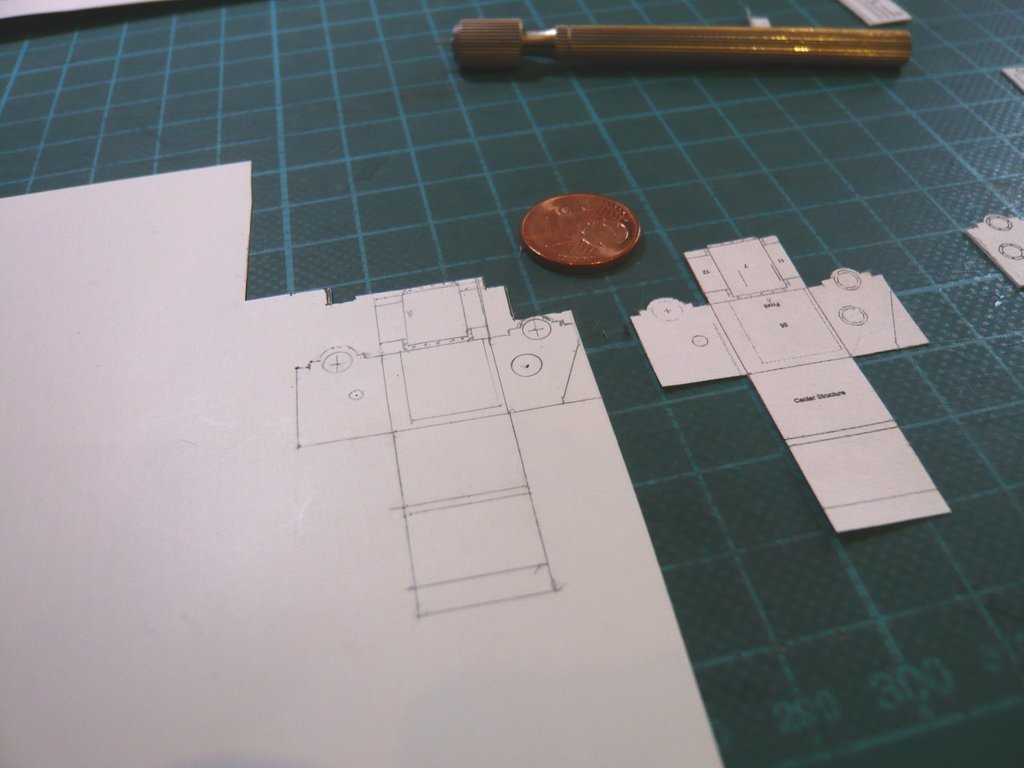

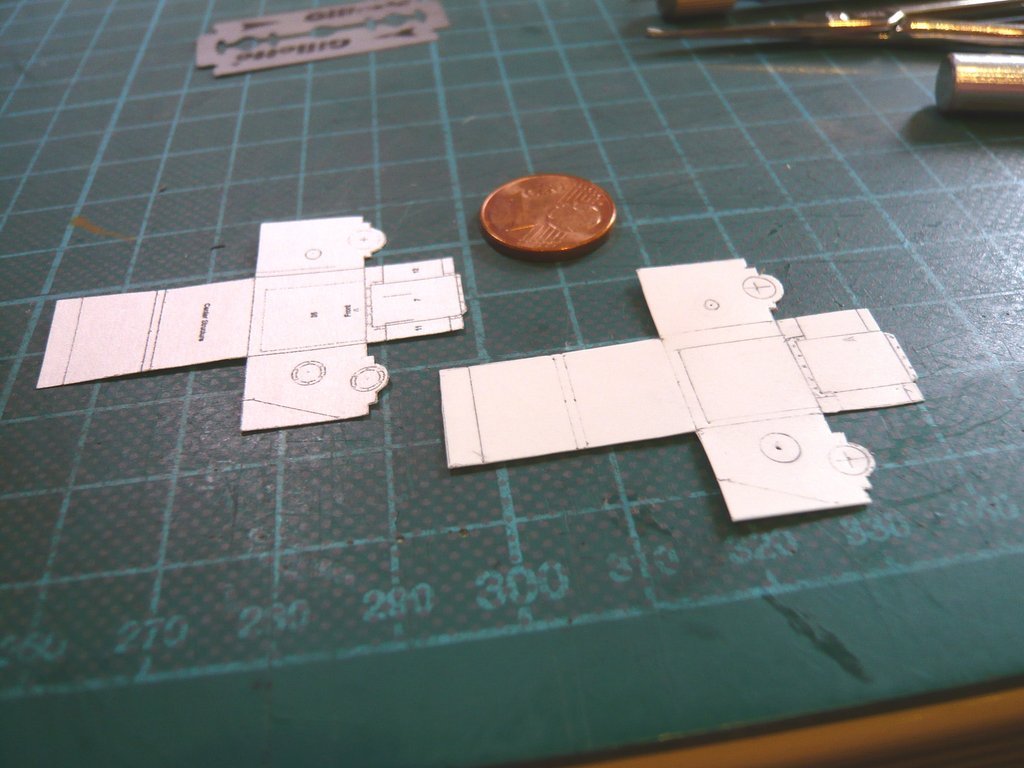

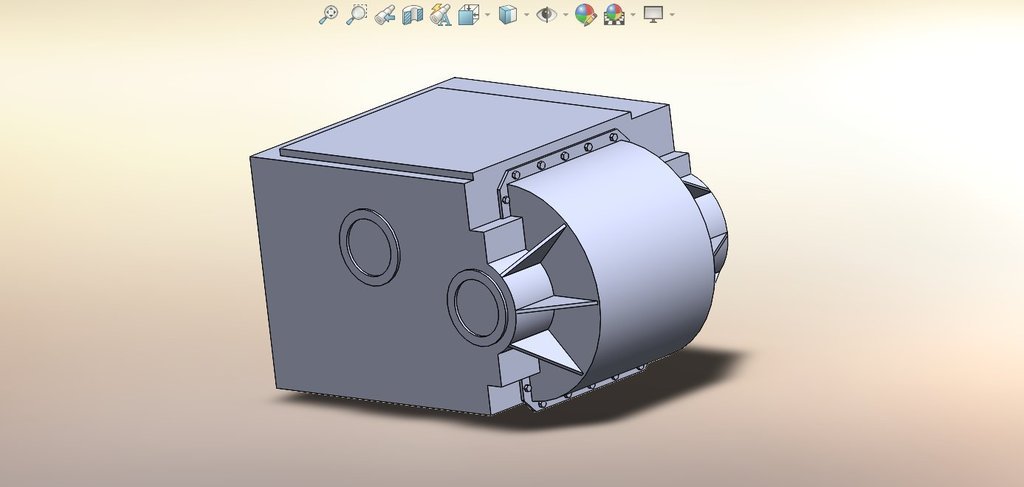

and how this was technically realized at the time on behalf of NASA is indeed an exciting thing that interested me in advance, as always.  The mere idea that the drive of these huge caterpillar tractors should be done by these comparatively measly Propel motors seemed a mystery to me at first,  but what has now become clear to me. but what has now become clear to me.  Thereto here is a worthwhile look into the opened gear housing on the multi-stage gear consisting of 10 gears and 5 shafts after the dismantling of the front gear unit with the huge Drive Sprocket, on which the extension drive shaft of the dismantled Propel motor can be seen.  Source: forum.nasaspaceflight.com (JayP) On its end sits a Propel pinion that engages in the dome-shaped attachment in a vertical Bevel gear, which can be seen very nicely on this overview drawing,   Source: NASA Technical Reports Server ( NTRS) just like in this impressive 3D model by a crawler expert from the NSF Forum (JayP).  Source: forum.nasaspaceflight.com (JayP) As was already be seen, this gear housing looks like this in the assembly instructions for Mischa Klement's Paper Kit.  Source: Micro Artwork, Mischa Klement (cyana) In his Truck 3D PDF, after long and stressful trials of the Acrobat Reader measurement tool, I have now succeeded in determining several measurement results at the same time and in the picture instead of a single measurement to hold on.   And these are the individual parts of the gear case printed out from the Outlines PDFs,  which I then glued back onto thin Evergreen Sheet Styrene (0,3 mm).  And from these puzzle pieces I will now try to scratch the gearbox housing. Let's see if and how well I can manage that.

__________________

Greetings from Germany Manfred Under construction: Launch Pad 39A with Challenger STS-6 (1:144) |

|

#2438

|

||||

|

||||

|

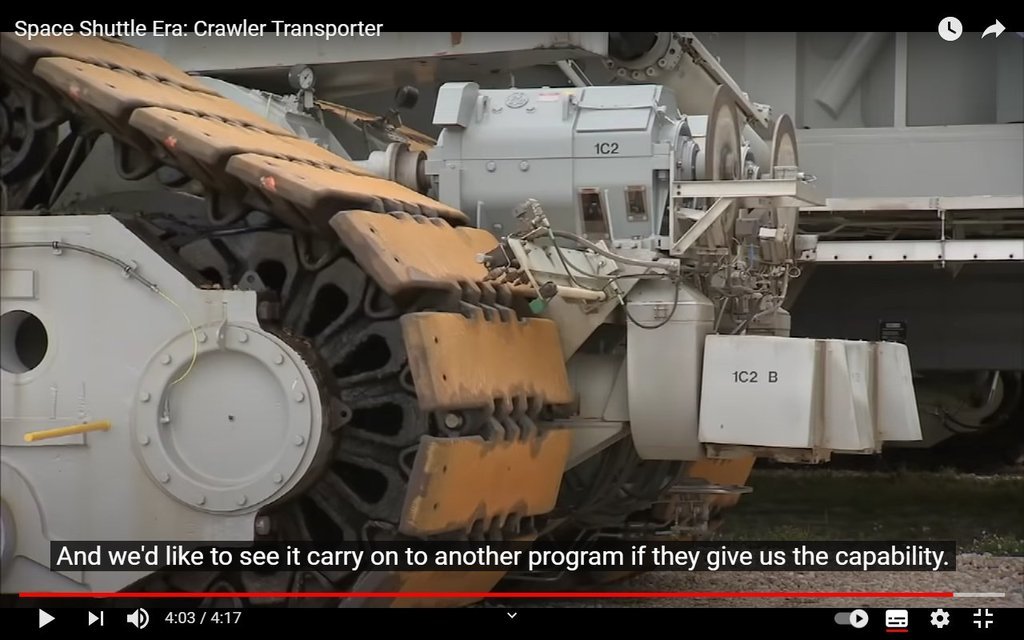

Hello everybody,

before I try scratch-building the Gear case, I would like to briefly come back to the Propel motors and show an interesting video sequence in which one can see the relatively slow running engines,   Source: NASA's Kennedy Space Center whereby I estimate that they run at a rotational speed of approx. 60 rpm.  BTW, this*video is so interesting that it should be watched in full length.*

__________________

Greetings from Germany Manfred Under construction: Launch Pad 39A with Challenger STS-6 (1:144) Last edited by spacerunner; 05-31-2021 at 05:13 PM. |

|

#2439

|

||||

|

||||

|

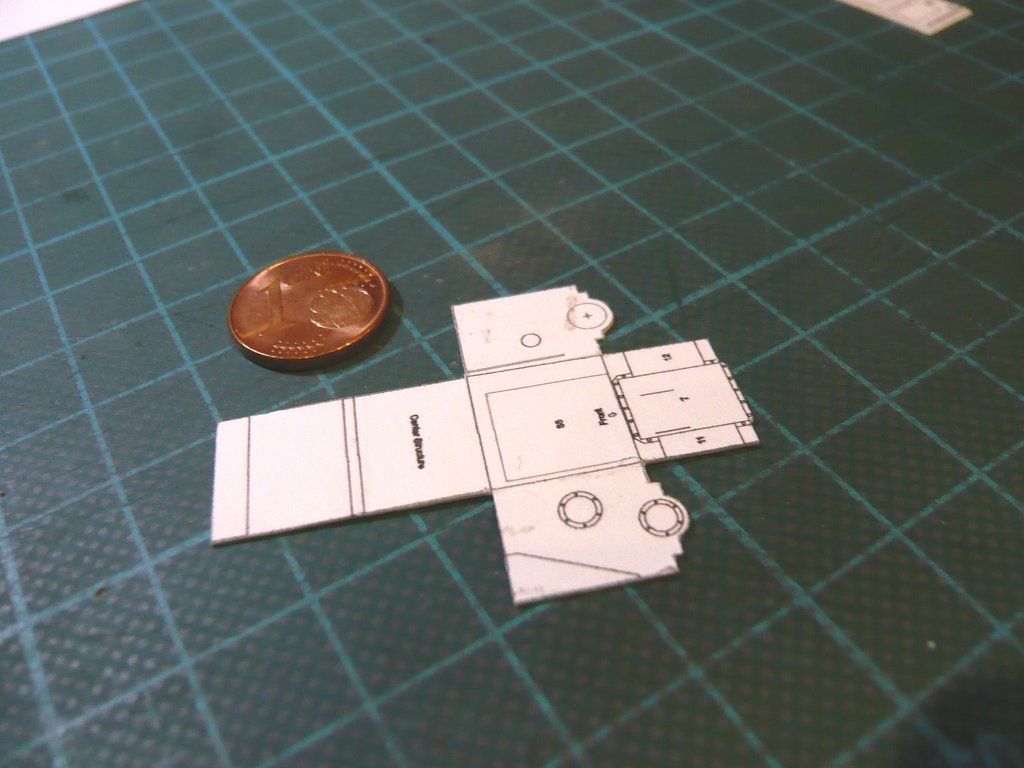

Hello everybody,

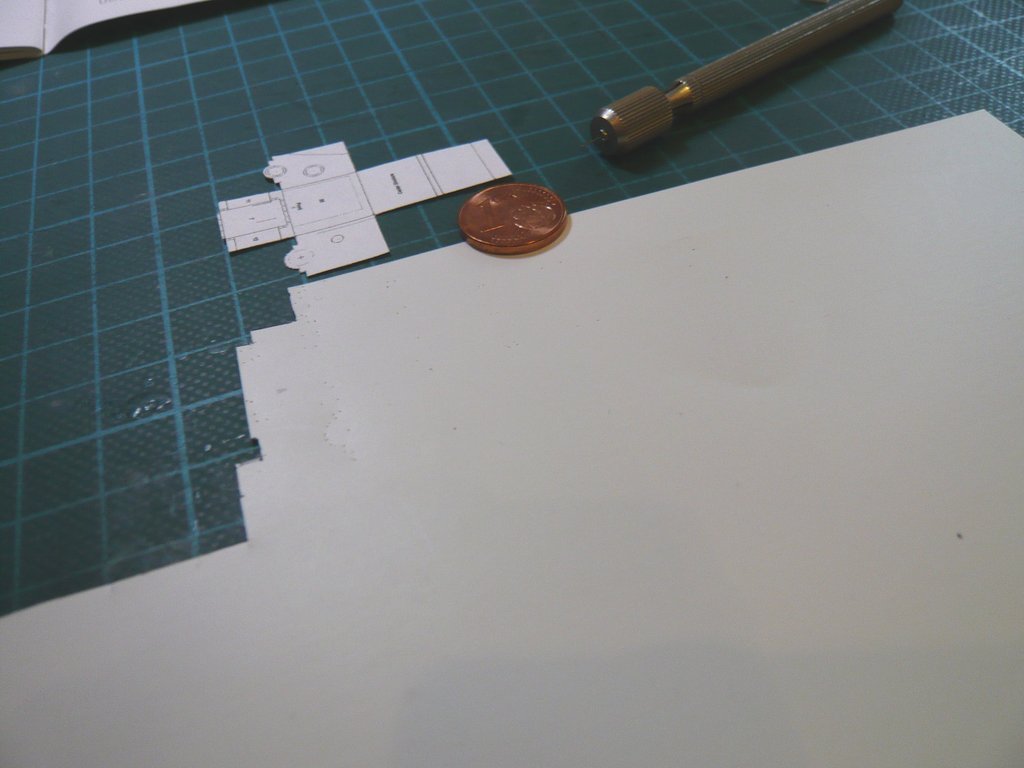

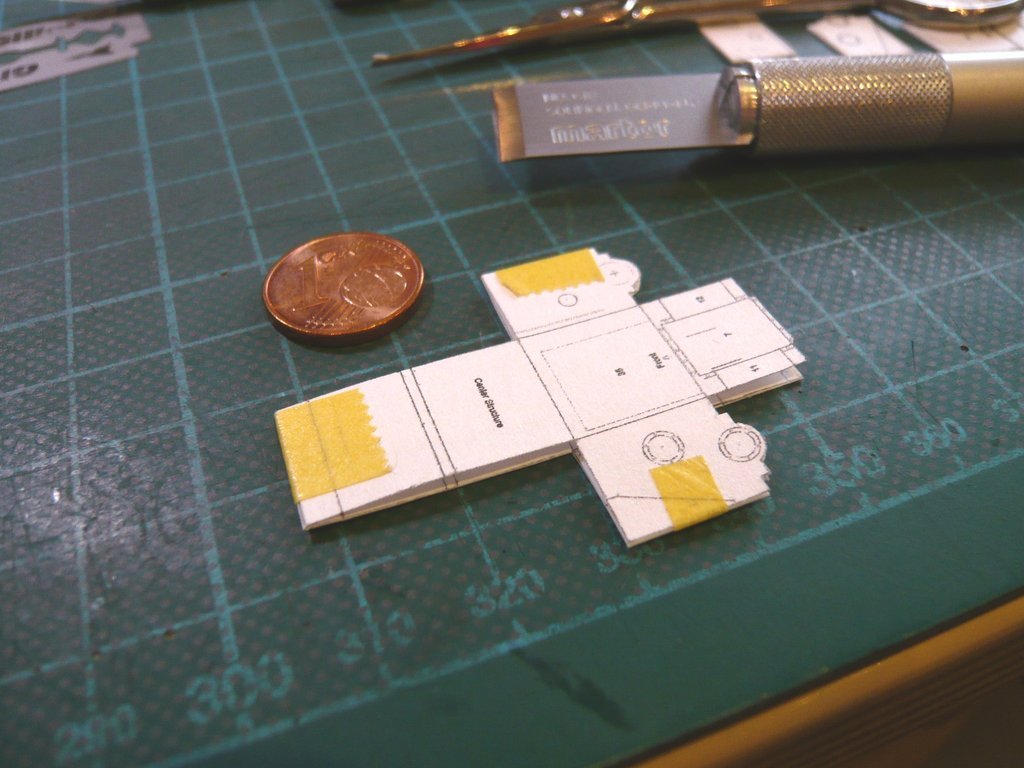

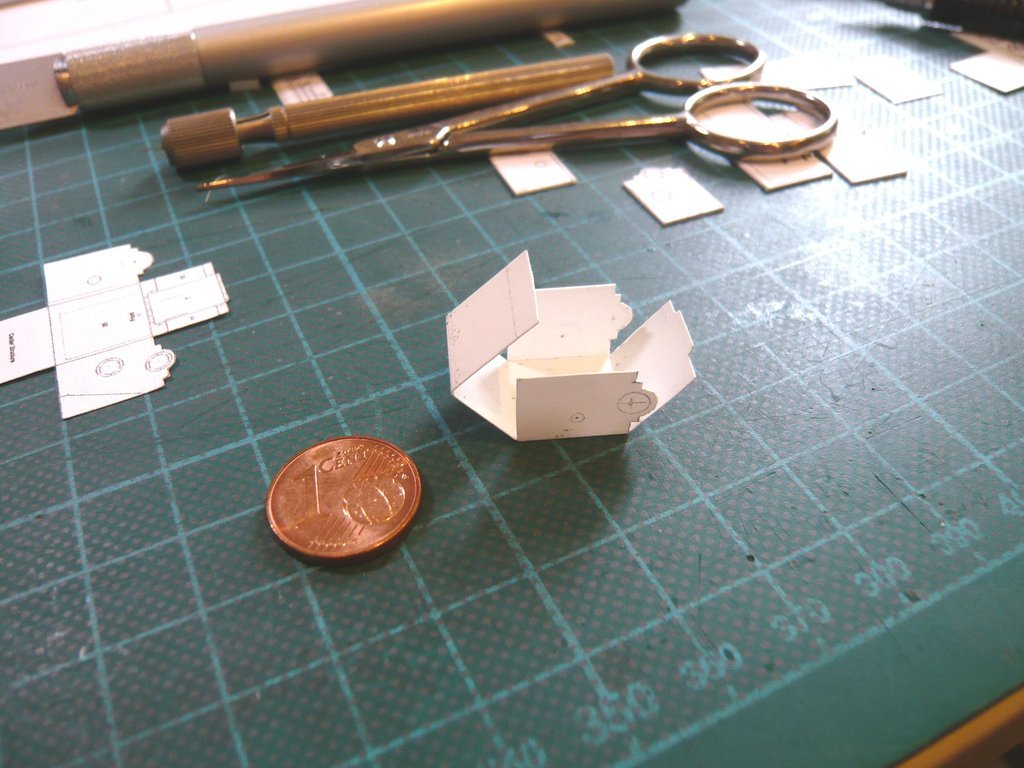

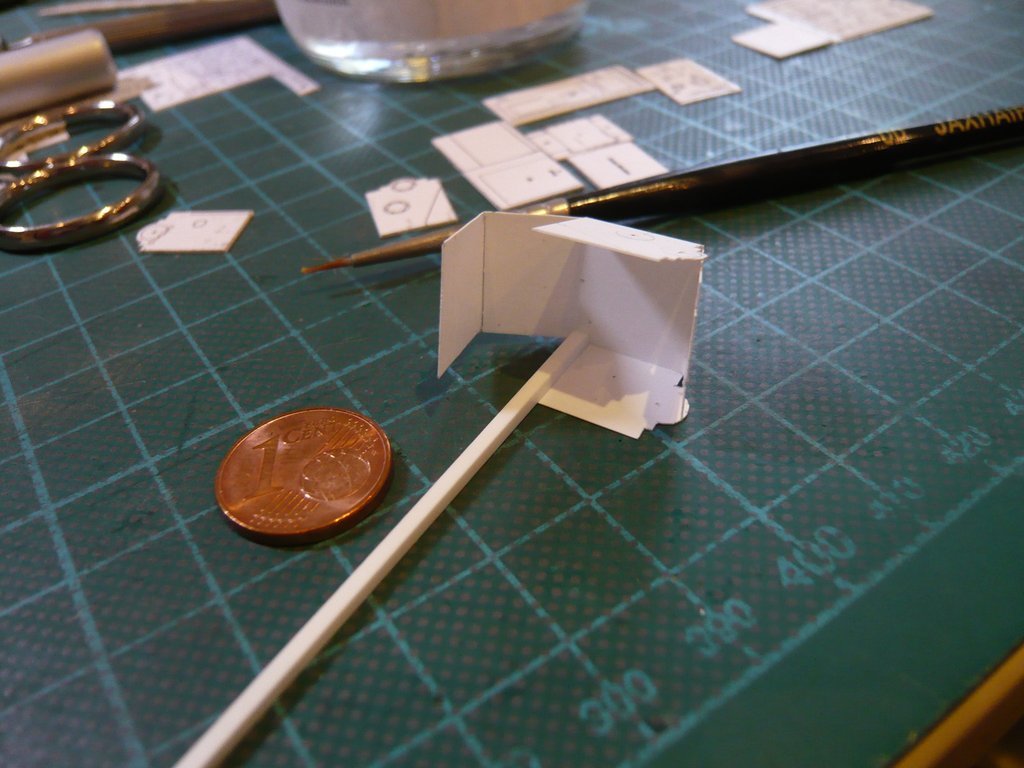

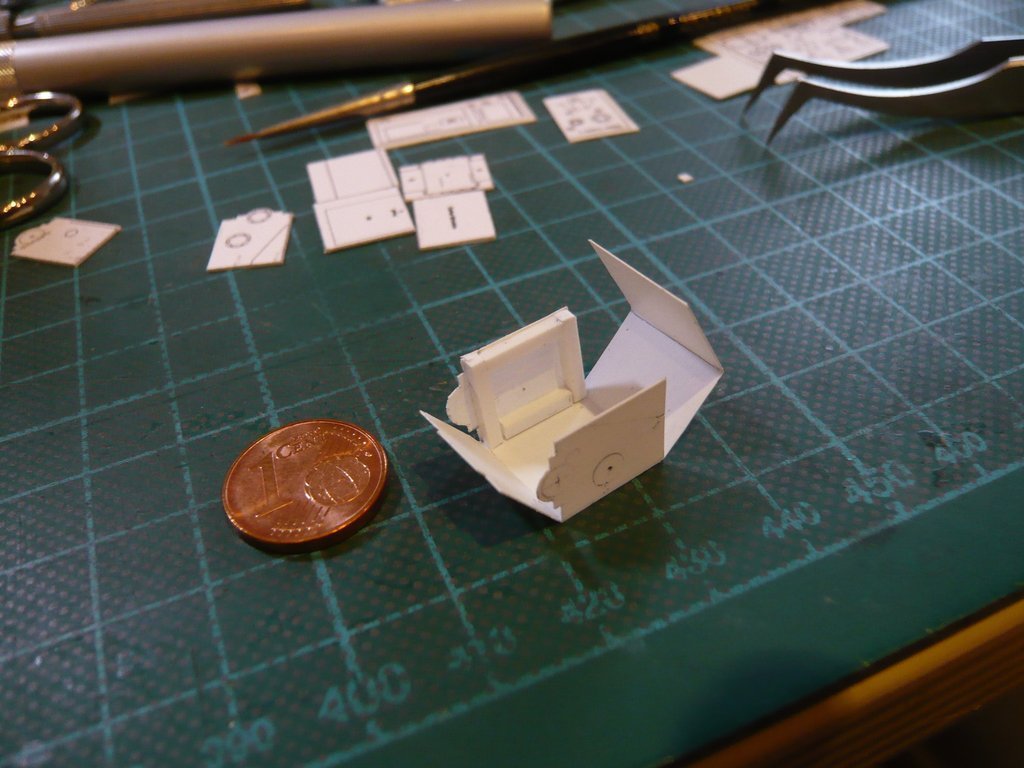

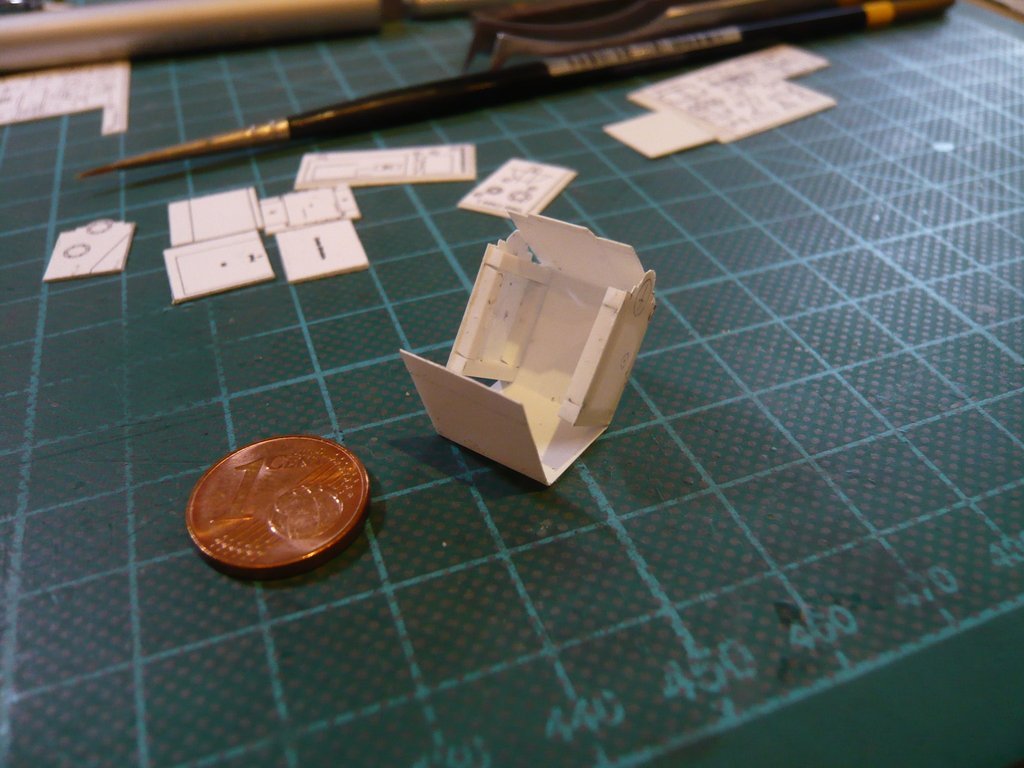

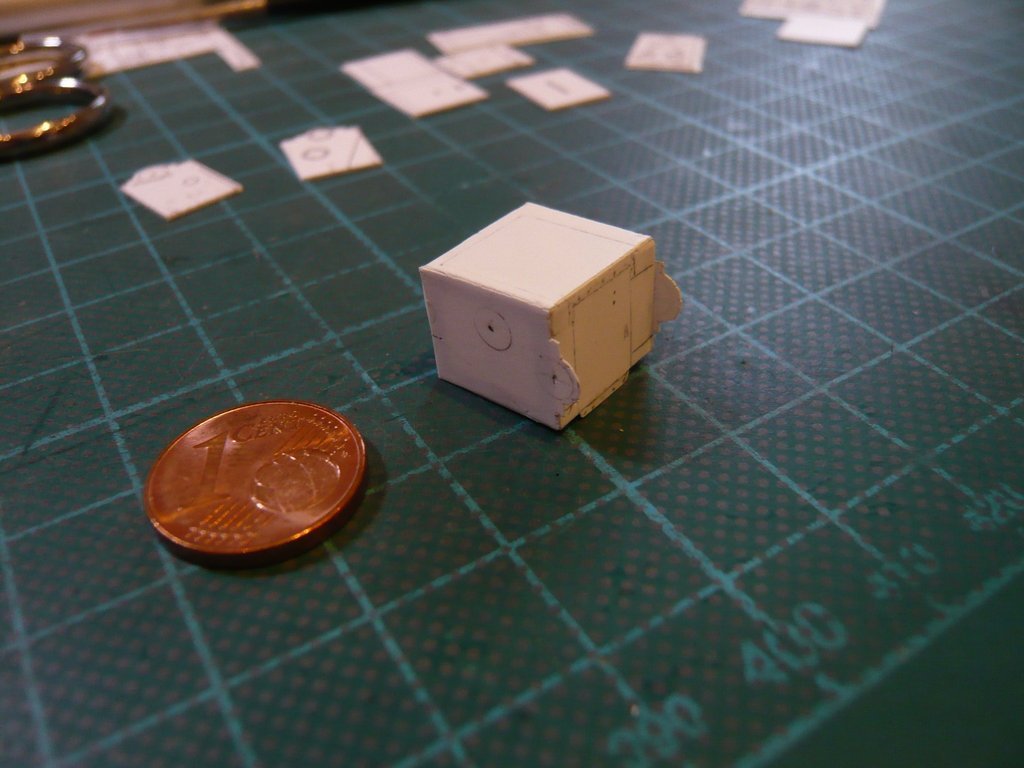

next I've punched out the basic body of the gear case (Part 1) with my wide Chisel cutter (Martor) from the Styrene Sheet (0,3 mm), whereby I have already noticed how stable this part is, so that folding and bending of the individual sides as in Paper construction is eliminated a priori.   That's why I first separated all parts from each other. But since these parts would lead to incorrect dimensions of the gear case when glued together due to their thickness, I had to realize that this variant would not be effective, which is why I've rescheduled.   Since I also have Styrene Sheet (0,15 mm), which corresponds to the normal paper thickness of the paper kit, I came up with the idea,  to cut out the part after transferring the outlines and to try to fold it like in paper construction and glue it to the edges. to cut out the part after transferring the outlines and to try to fold it like in paper construction and glue it to the edges.  First I tried to fold a small piece like an angle by holding it under a steel ruler and bending it up with the chisel cutter, which I succeeded in doing.  To transfer the contours, I've then pierced all the corner points of the template with a thin needle (0,3 mm),  what will probably hardly be seen,   which I've then connected with a pencil, which in turn was balm for the eyes.   Then I've cut out the part with a fine scissors and slightly reworked the edges using the laid on template.   Then I folded the part edge by edge under the steel ruler.  Since gluing the edges edge to edge seemed too risky to me, I've glued in small Evergreen sticks (1,5 x 1,5 mm) inside as adhesive edges and for stabilization.    As a result, gluing the base body was no longer rocket science.

__________________

Greetings from Germany Manfred Under construction: Launch Pad 39A with Challenger STS-6 (1:144) |

|

#2440

|

||||

|

||||

|

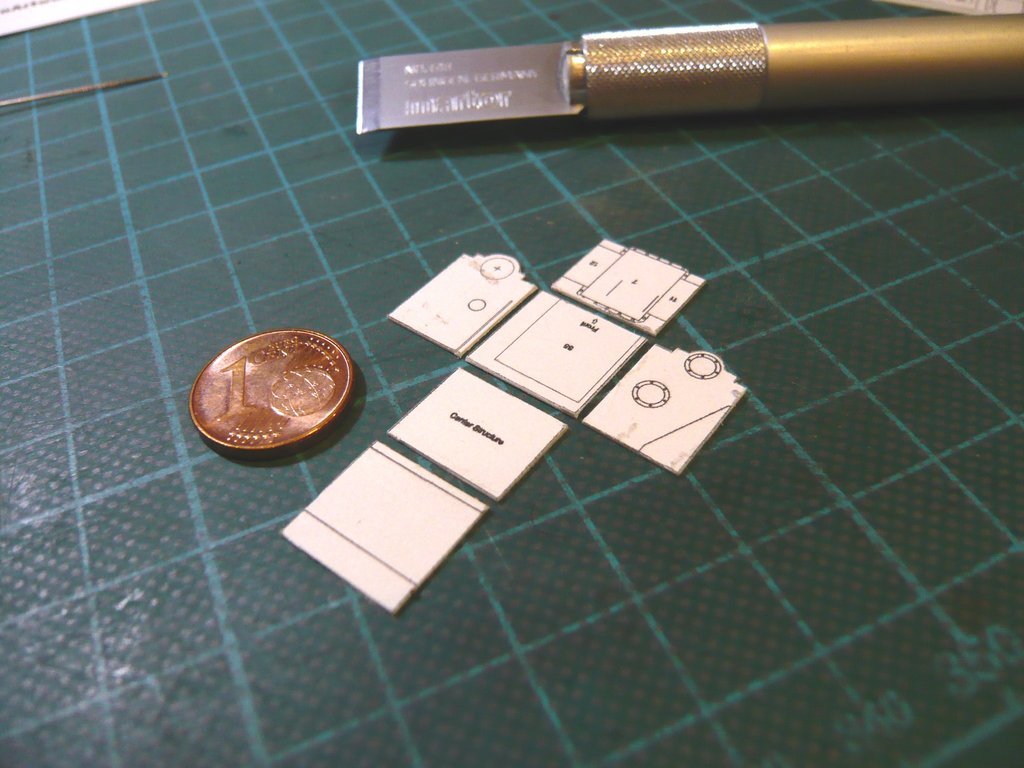

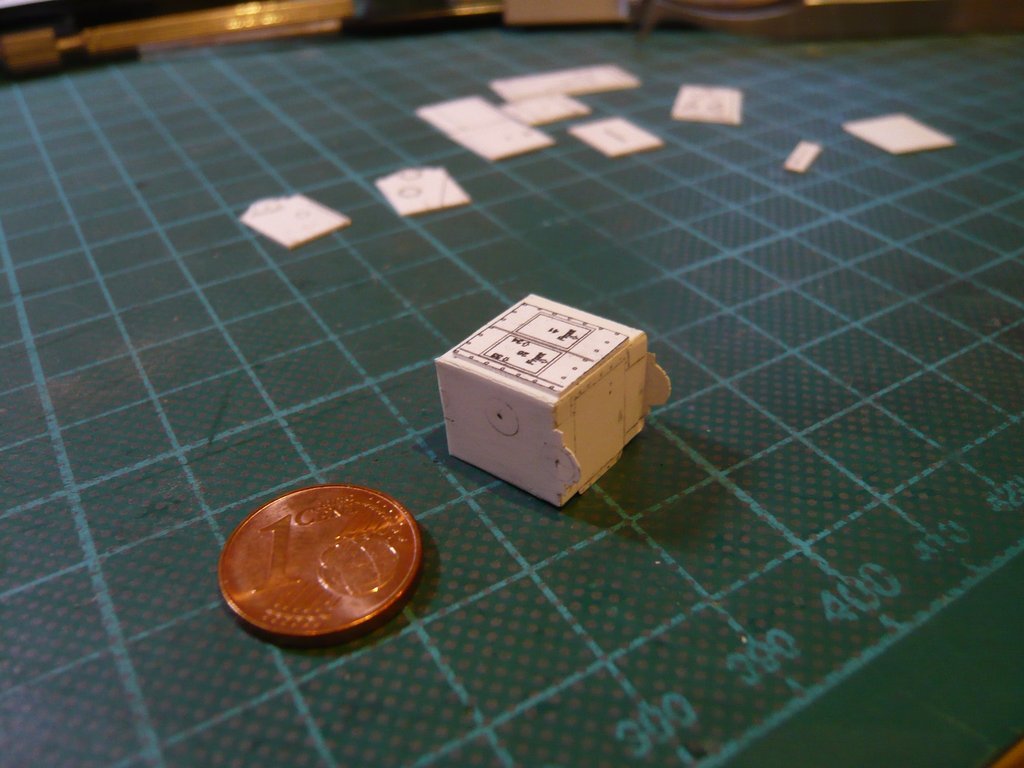

Then I've glued on the Base plate (Part 35) made of 0,3 mm sheet, on which the dome-shaped attachment for holding the Propel motor shaft will sit.

And my ARC friend Joe has already started with the gear case and delivered a first image of his 3D model, which looks great.   Source: ARC Forums (crackerjazz) And next I'll try my hand at this semicircular casing.

__________________

Greetings from Germany Manfred Under construction: Launch Pad 39A with Challenger STS-6 (1:144) |

|

|

|